Inaccurate measurements costing your business? Faulty data leads to waste and inefficiency. Load cells provide the precise force data needed to fix this issue and improve your operations.

A load cell is an electromechanical sensor. It converts mechanical force, like weight or tension, into a measurable electrical signal. This core function allows it to be used in everything from simple retail scales to complex industrial automation and structural monitoring systems for precise measurement.

This simple device is the foundation of modern weighing. But how does it actually perform its many functions, and where do you see it in action every day? Let's explore its diverse roles. This will help you understand why it's so critical for countless industries.

What are the primary functions of a load cell?

Need to do more than just weigh things? Your operations require versatile measurement of different forces. Load cells are designed for more than just weight; they handle tension, compression, and more.

The primary function of a load cell is converting mechanical force into an electrical signal. This allows for precise weight measurement, material monitoring in automation, force testing for safety compliance, and structural load monitoring in civil engineering projects. It is a versatile force transducer.

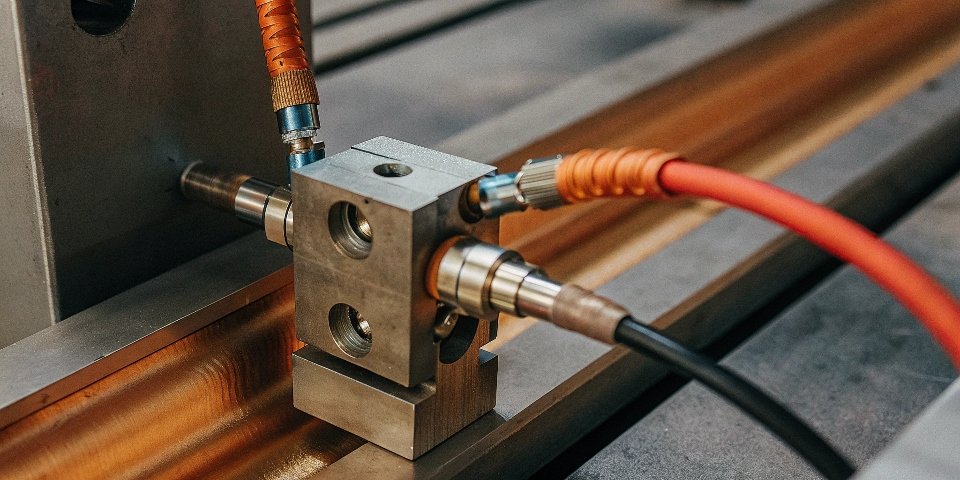

A load cell isn't a one-trick pony. Its ability to translate physical force into data opens up a wide range of functions that are crucial for modern industry. These functions go far beyond a simple bathroom scale. At Weigherps, we help our clients leverage these capabilities to improve their processes. For example, a food manufacturer uses our load cells1 not just to weigh final products, but also to control the mixing process by accurately dispensing ingredients. This ensures consistency and reduces waste. Another client in civil engineering uses our products to monitor the tension in support cables on a bridge, providing essential safety data. The core value lies in turning physical forces into actionable information.

Core Measurement Functions

The functions can be grouped into a few main categories.

| Function | Description | Common Example |

|---|---|---|

| Weighing | Measuring the mass or weight of a static or dynamic object. | Platform scales, truck scales, checkout lanes. |

| Force Testing | Measuring tension (pulling) or compression (pushing) forces. | Material strength testing, component safety checks. |

| Process Control | Monitoring material flow or quantity in an automated system. | Batching systems, conveyor belt scales, tank weighing. |

| Structural Monitoring | Measuring the load, stress, and strain on physical structures. | Bridge load monitoring, building stability checks. |

What are the most common industrial applications for load cells?

Wondering where these sensors fit into the real world? It is hard to see their impact. Load cells are the hidden heroes in countless industries, from making your food to building your car.

Load cells are commonly used in manufacturing for process automation and quality control. You find them in agriculture for silo weighing, in logistics for pallet and truck scales, in healthcare for medical devices, and in aerospace for component testing. Their applications are incredibly diverse.

Load cells are everywhere, even if they are not visible. Their reliability and precision make them indispensable in any industry that relies on accurate weight or force data. I remember a client in the food and beverage industry who struggled with inconsistent batch sizes. We helped them integrate our hygienic, stainless-steel load cells into their mixing tanks. Now, they measure ingredients with gram-level accuracy. Their product quality improved, and they saved thousands in wasted materials. This is a classic example of load cells driving efficiency. We see similar stories in other sectors. In logistics, our load cells are in warehouse scales that ensure trucks are not overloaded. In the medical field, they are used in sensitive equipment like infusion pumps and patient lifts. Each application requires a specific type of load cell, and that's where our 18 years of experience comes in. We help clients choose the perfect solution.

How do load cells work to measure force and weight?

Does the technology behind load cells seem like a black box? It's confusing how a metal block measures weight. The principle is simple: it measures tiny changes in its shape to calculate force.

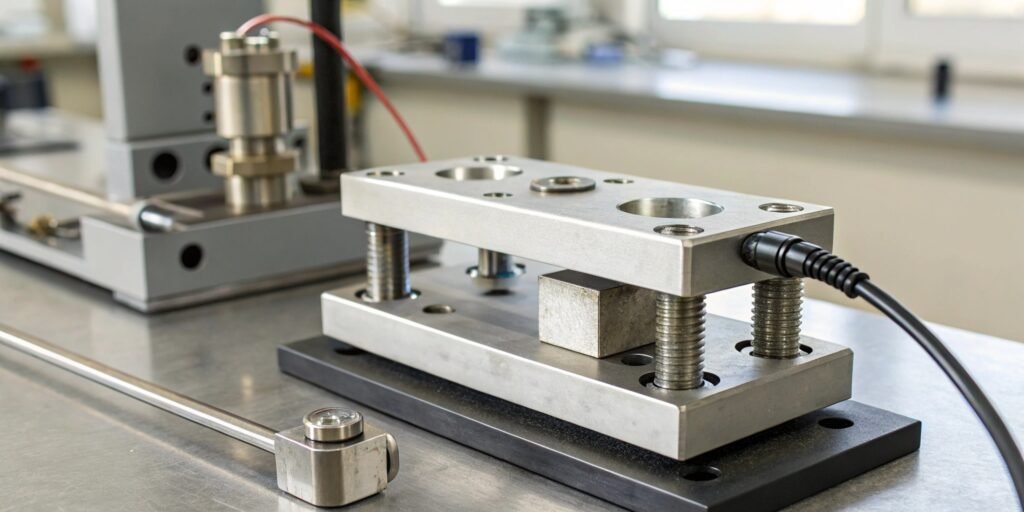

A load cell works using a strain gauge. When a force is applied, the load cell's metal body deforms slightly. Strain gauges attached to it also deform, changing their electrical resistance. This change is measured and converted into a digital weight or force reading.

The process is a fantastic piece of engineering, but it's easy to understand. Let's break it down into simple steps.

- Force is Applied: An object is placed on a scale, or a force pulls or pushes on the load cell.

- The Body Deforms: The metal body of the load cell, usually made of steel or aluminum, bends or compresses by a microscopic amount. This deformation is elastic, meaning it returns to its original shape when the force is removed.

- Strain Gauges Stretch: Tiny, foil-like sensors called strain gauge2s are bonded to the load cell's body. As the body deforms, these gauges stretch or compress with it.

- Resistance Changes: Stretching or compressing the strain gauges changes their electrical resistance. The change is very small but proportional to the force applied.

- Signal is Measured: The strain gauges are wired together in a circuit called a Wheatstone bridge. This circuit can detect the tiny change in resistance and output a small voltage signal. This signal is then amplified and converted into a human-readable value, like kilograms or pounds.

It is all about this reliable, repeatable process. We use high-quality materials to ensure our load cells can do this millions of times without losing accuracy.

Why are load cells essential for creating accurate weighing systems?

Building a weighing system that you can trust? Inaccurate data makes the whole system useless. A high-quality load cell is the single most critical component for ensuring reliable and precise results.

Load cells are essential for accuracy because they are the primary sensor that directly interacts with the force. Their design, material quality, and calibration determine the system's precision, repeatability, and reliability. Without a quality load cell, any attached electronics or software is working with bad data.

A weighing system is a chain of components, but the load cell is the first and most important link. For our clients who are software vendors, this point is critical. Your advanced software is only as good as the data it receives. If you connect your analytics platform to a flawed weighing system, your insights will be wrong. We call this 'garbage in, garbage out.' A high-quality load cell provides the clean, reliable data your software needs to perform correctly.

Several factors contribute to a load cell's accuracy.

- Materials: We use specialized steel and aluminum alloys that have predictable and stable elastic properties.

- Design: The physical shape of the load cell is engineered to isolate and measure force from a specific direction, ignoring other forces.

- Strain Gauges: The quality of the strain gauges and the adhesive used to bond them determines their sensitivity and long-term stability.

- Calibration: Every one of our load cells is carefully calibrated against known standard weights. This ensures the electrical output correctly corresponds to a specific force.

Before any product leaves our factory, our quality inspection department puts it through comprehensive tests. This ensures that the data you get is a true reflection of the physical world.

Conclusion

In summary, load cells are the foundational sensors for any accurate weighing or force measurement system. Their function and quality are critical for modern industrial operations and data-driven decisions.

[…] the simple stuff. These factors seem small, but they have a huge impact on modern, sensitive load cells1. We often find the problem can be fixed in minutes, right over the phone. After years of […]

[…] A 60-ton capacity is standard. But if you need to weigh heavier loads, the internal structure and load cells4 must be stronger. This increases the […]

[…] basic bridge circuit has four resistors. In many sensor applications, like the load cells3 we manufacture at Weigherps, one of these resistors is a variable sensor. This sensor changes its […]

[…] load cell4 is the heart of the scale. Its quality determines the foundation of your accuracy and […]

[…] its core, a load cell5 is a transducer. That's a technical term for a device that converts one form of energy into […]