Getting an inaccurate weight can cause big problems. You trust your scales every day for your business. But if you don't understand how they work, you can't be completely sure they are accurate.

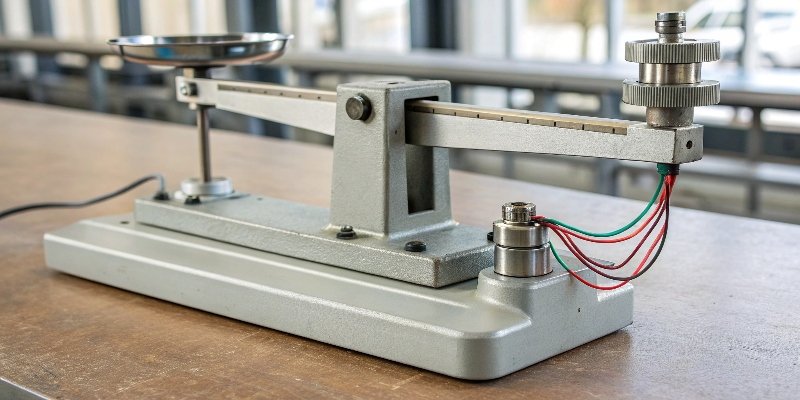

A weighing machine works by converting physical force into an electrical signal. A sensor, called a load cell, feels the weight and creates a tiny voltage. This signal is then amplified, converted into a digital value, and displayed as the final weight reading you see on the screen.

I've been in the industrial scale1 business for 18 years. I've seen how a deep understanding of these principles helps our clients make better purchasing decisions. It moves the scale from being just a tool to being a reliable part of their production system. The technology seems complex, but the idea behind it is straightforward. Let's break it down so you can feel more confident about the weighing equipment that your operations depend on every single day.

What is the principle of a weight machine?

Do you see your weighing machine as a black box? This makes it hard to troubleshoot problems or choose the right new equipment for a specific need. We can help clear that up.

The core principle involves a load cell sensor. When you place an object on the scale, the sensor structure bends just a little bit. Strain gauges inside the sensor change their electrical resistance. This change creates a voltage signal that is directly proportional to the applied weight.

This journey from a physical force to a digital number is at the heart of every modern electronic scale. As a manufacturer, we focus on making every step of this process as precise as possible. Here is a closer look at how it happens.

The Core Conversion Process

-

Gravity Sensing: First, the object's weight is transferred through the scale platform to the sensor. This sensor contains a precisely engineered metal structure called an elastic body. The weight causes this body to deform by a microscopic amount. Bonded to this body are strain gauges2, which are essentially tiny wires. When the elastic body deforms, these wires stretch, changing their electrical resistance. We arrange these gauges in a setup called a Wheatstone bridge3. The tiny change in resistance unbalances the bridge, which produces a very small voltage signal, usually around 2 millivolts for every volt of excitation.

-

Signal Processing: This millivolt signal is too weak to be useful on its own. It first goes to an amplifier, which boosts its strength. Then, it's filtered to remove any electrical noise. Finally, an Analog-to-Digital Converter (ADC)4 translates this clean analog voltage into a digital number. A microprocessor5 then takes this number and displays it as a weight, achieving accuracies up to 0.01% of the full scale.

How does a weighing machine know the weight?

How does a heavy truck’s weight become a number on a screen? It seems like magic. But it’s a precise engineering process that turns physical force into reliable digital data.

A weighing machine "knows" the weight by processing the electrical signal from its sensor. A microprocessor uses a pre-set calibration factor to translate the final digital number from the ADC into a familiar unit of weight, like kilograms or pounds, which is then shown on the display.

The accuracy of the final weight depends entirely on the quality of each component in the signal chain. For our clients, especially software vendors who need to integrate with our hardware, understanding these components is key. It helps them appreciate the quality and reliability of the data our scales provide.

From Signal to Screen

The quality of the final weight reading is a result of several high-precision components working together. Each one plays a critical role.

| Component | Function | Typical Precision |

|---|---|---|

| Sensor (Load Cell) | Converts the physical force of weight into an electrical signal. | Non-linearity error ≤0.03% |

| Amplifier | Boosts the weak sensor signal to a standard, usable level. | Gain error ±0.05% |

| A/D Converter (ADC) | Changes the continuous analog signal into a discrete digital number. | 24-bit resolution, error ±0.001% |

The sensor is the first point of contact; its accuracy is fundamental. The amplifier must boost the signal without introducing its own errors. Finally, the ADC's resolution determines the smallest weight increment the scale can detect. A 24-bit ADC, for example, provides over 16 million divisions, allowing for incredibly fine measurements. The system's sampling frequency, typically between 50 to 200 times per second (Hz), is also critical. For dynamic weighing6, like a truck driving over a scale, we ensure a sampling rate of at least 100Hz to capture the weight accurately without motion blur.

What is weighing machine calibration?

Your scale says 100 kg. Is it really 100 kg? Inaccurate readings cost you in materials, money, and compliance. Proper calibration is what builds trust in your measurements and your business.

Weighing machine calibration is the process of checking a scale's accuracy using a known, certified weight. We compare the scale's reading to the standard weight. Then we make adjustments to eliminate any errors, ensuring the scale is reliable across its full weighing range.

As manufacturers, we see calibration as a fundamental step in quality control. It's not just about setting the scale correctly once. It's about having systems in place to maintain that accuracy over time and under different conditions.

Ensuring Accuracy Through Calibration

We can't just rely on high-quality components. We must actively manage and correct for potential errors. That's where calibration and other compensation mechanisms come in. The most common method is a three-point calibration. We use standard, certified weights to check the scale at zero, at its full capacity (span), and at a point in the middle (linearity). This ensures the scale is accurate not just at the extremes but across its entire working range.

Beyond this, we build in other protections. Temperature changes can affect a sensor's resistance. So, we build in temperature compensation7, often with a thermistor, to automatically correct for drift between -10°C and 40°C. For dynamic weighing, simple calibration isn't enough. We use advanced dynamic weighing algorithms. These algorithms can filter out the "noise" from vehicle vibrations, often with help from other sensors like accelerometers, to get an accurate weight even when the object is moving. This keeps errors below ±0.5% in tough conditions.

What is the working principle of a weighing balance?

Do you think of your weighing system as just a simple tool? Today’s scales are smart and connected. You might be missing out on powerful new ways to improve your factory's operations.

The principle for a modern weighing balance is still about turning force into an electrical signal. But now, they include advanced features like IoT connections for cloud data. They also have special designs, like explosion-proof models for safer work in hazardous areas.

The foundational principle hasn't changed, but its application has evolved dramatically. We now use this basic principle to build intelligent weighing systems that become active parts of our clients' data infrastructure.

The Principle in Action: Smart Weighing Systems

The core principle is now the foundation for powerful, integrated systems. For example, a 100-ton truck scale is so sensitive that its load cell8 sensor deforms by only 0.1mm under full load. This tiny change is what we measure. But we don't just display the weight anymore.

Modern intelligent weighbridges, or truck scales, now have IoT functionality. They can be equipped with cameras for license plate recognition and video monitoring. The weight data, along with the vehicle ID and images, can be automatically uploaded to a cloud platform via industrial interfaces like RS485 or wireless 4G connections. This provides our software clients with rich, real-time data for their management systems.

Furthermore, we apply this principle in specialized environments. For the oil and gas industry, we design explosion-proof systems with intrinsically safe sensors. These devices are engineered to prevent any spark, ensuring safe operation in hazardous atmospheres. The simple principle of measuring force becomes a critical safety and data-gathering tool in the most demanding industrial settings.

Conclusion

Understanding a scale’s core principle—from physical force to a digital signal—helps you choose the right equipment. This knowledge ensures accuracy, reliability, and better integration into your business systems.

-

Explore the unique features of industrial scales and their importance in various industrial applications. ↩

-

Discover how strain gauges contribute to the accuracy of load cells and the technology behind them. ↩

-

Explore the Wheatstone bridge setup and its importance in measuring electrical resistance changes. ↩

-

Understand the critical function of ADCs in converting analog signals to digital data for precise weight readings. ↩

-

Learn about the microprocessor's function in processing weight data and displaying accurate readings. ↩

-

Learn about dynamic weighing techniques and how they ensure accurate measurements in motion. ↩

-

Discover how temperature compensation helps maintain accuracy in varying environmental conditions. ↩

-

Learn about load cells, the heart of weighing machines, and their role in ensuring accurate measurements. ↩

[…] Analog-to-Digital Converter (ADC)4: The tiny voltage from the load cell is an analog signal. The ADC measures this signal and […]