Struggling with safety and consistency in chemical automation? Manual errors can ruin entire batches and create hazards. Industrial scales provide the precision needed to automate processes safely and reliably.

Industrial scales are the foundation of chemical industry automation. They provide high-precision weight data for raw material mixing, process control, and final product packaging, enabling automated systems to ensure safety, efficiency, and consistent quality, forming the backbone of smart manufacturing.

This precise control is just the beginning of what these devices can do. They bring a level of accuracy and data integration that was once impossible, transforming how chemical plants operate. To truly understand their impact, we first need to look at the different jobs these scales perform. Let's explore their fundamental applications and see how they build the platform for full automation.

What are industrial scales used for?

Managing large inventories and production flow is a constant headache. Small inaccuracies add up, leading to waste, cost overruns, and compliance issues. Industrial scales offer a clear, precise solution.

Industrial scales are used for weighing raw materials, monitoring in-process inventory, checking finished goods, and ensuring shipping accuracy. They are vital for inventory management, quality control, logistics, and meeting regulatory compliance across many industries.

At my company, we've seen firsthand how these scales become the central point of control for our clients. It's not just about one measurement; it's about creating a chain of accurate data points throughout the entire production cycle.

Common Applications of Industrial Scales

Think of your operation from start to finish. Scales play a role at almost every step. They provide the hard data you need to make smart decisions, control costs, and maintain quality. A software vendor I worked with needed to integrate weighing data into their client's ERP system. We provided scales with advanced connectivity that allowed them to track everything in real-time. This is how different scales support the workflow:

| Application Area | Primary Function | Key Benefit |

|---|---|---|

| Shipping/Receiving | Verifying weights of incoming and outgoing goods | Prevents over-payment/under-delivery |

| Inventory Management | Counting parts and tracking stock levels | Optimizes stock and reduces waste |

| Production/Batching | Measuring ingredients for specific formulas | Ensures product consistency |

| Quality Control | Checking final product weight against standards | Maintains quality and compliance |

What is the use of an electronic scale in chemistry?

Chemical reactions demand extreme precision. A tiny measurement error can compromise the reaction, ruin an entire batch, and waste valuable materials. Electronic scales deliver the accuracy chemists need.

In chemistry, electronic scales are used for the precise measurement of chemicals and reagents for experiments, formulation, and quality analysis. Their high accuracy is essential for creating solutions, ensuring correct reaction ratios, and verifying product yield.

This need for precision is something I discuss with clients all the time, especially those in specialty chemicals. The difference between a successful product and a failed one can come down to a single milligram.

The Precision Imperative in Chemical Processes

In the world of chemistry, "close enough" is never good enough. Accuracy is everything. While a large floor scale might be perfect for weighing a pallet of raw materials, creating the actual chemical formula requires a different level of precision. This is where electronic scales1 are critical. For example, a client who produces specialty paints needed to add a tiny amount of a very expensive additive. We provided them with a high-precision bench scale connected to their automated dispenser. This system ensured the perfect amount was added every single time, saving them money and guaranteeing a consistent product. These scales are vital for:

- Formulation: Mixing chemicals in exact, repeatable ratios to create a consistent product.

- Quality Control (QC): Testing small samples from a large batch to ensure the entire batch meets quality specifications.

- Research & Development (R&D)2: Developing new products where every measurement must be recorded perfectly to replicate success.

What are scales used for in chemistry?

Scaling a lab formula to full-scale production is filled with risk. A formula that works perfectly in grams might fail spectacularly when you try to make it in tons. Scales bridge this gap.

Scales in chemistry function at every stage, from R&D on lab balances to pilot-plant testing on bench scales and full production using tank weigh modules. They ensure precise lab formulas are accurately replicated during large-scale manufacturing.

Helping clients scale up is one of the most rewarding parts of my job. We're not just selling a piece of equipment; we're providing the tools they need to grow their business safely and effectively.

From Laboratory Beakers to Industrial Reactors

The journey of a chemical product involves scales of different sizes and precision at each step. The goal is to maintain the integrity of the original formula as the volume increases. A mistake at any stage can be costly. We help our clients choose the right weighing solution for each phase of their process, ensuring a smooth transition from the lab to the factory floor. This tiered approach is fundamental to success in the chemical industry.

| Production Stage | Type of Scale Used | Key Function |

|---|---|---|

| 1. Research & Development | Analytical & Precision Balances | Develop formulas with high accuracy (mg/µg) |

| 2. Pilot Production | Bench & Compact Scales | Test formulas at a small scale (grams/kg) |

| 3. Full Manufacturing | Floor Scales, Tank & Hopper Scales | Produce large batches with industrial accuracy (kg/tons) |

This progression ensures that the precise ratios discovered in the lab are maintained, guaranteeing product quality and consistency no matter the batch size.

How does an industrial scale work?

You depend on industrial scales every day, but do you know how they work? Not understanding the technology can make it difficult to choose the right one for your specific needs.

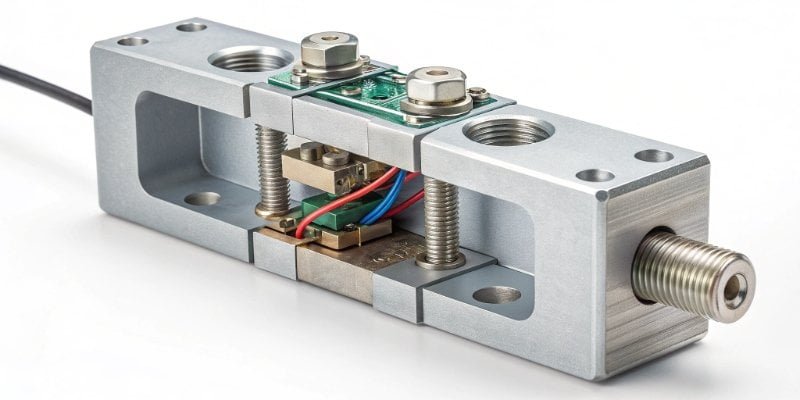

Most modern industrial scales use a load cell. When weight is applied, the load cell deforms slightly. This changes the electrical resistance of internal strain gauges, which is then converted into a digital signal that an indicator displays as a weight reading.

The technology itself is impressive, but my focus is always on how it solves a client's problem. We choose the right components to build a scale that will perform reliably in their specific environment.

The Technology Behind the Measurement

Understanding the core components of an industrial scale helps you appreciate why choosing the right one is so important for automation. The process is a simple chain of events that turns physical force into useful data.

-

The Load Cell: This is the heart of the scale. It's a sensor that converts the force of weight into a tiny electrical signal. For chemical plants, we often use stainless steel, hermetically sealed load cell3s that can withstand corrosive materials and harsh washdowns.

-

The Strain Gauge: Inside the load cell, a grid of fine wire called a strain gauge stretches or compresses when weight is applied. This physical change alters its electrical resistance.

-

The Signal Converter (A/D): The small, analog change in resistance is sent to a converter. This device turns it into a stable, digital signal that computers and other automated equipment can understand.

-

The Indicator/Controller: This is the brain. It takes the digital signal, displays it as a weight (like kg or lbs), and can send that data to a PLC, PC, or control system to trigger an action, like closing a valve or starting a mixer.

Conclusion

Industrial scales are not just measurement tools. They are the data-driven foundation for safe, efficient, and consistent automated chemical production, enabling true smart manufacturing and powerful business growth.

Comments (0)