Struggling to decode the tech inside smart scales? The variety of sensors can be confusing, making it hard to choose the right one for your product integration.

Modern smart scales primarily use strain gauge sensors for high accuracy and low cost. They also incorporate capacitive sensors for moisture resistance and piezoelectric sensors for dynamic measurements, often enhanced with MEMS technology and digital signal processing for advanced features like body composition analysis.

Understanding the core sensor is just the beginning. The real magic happens in how these tiny components work together to deliver precise data. Let's peel back the layers and explore the specific types of sensors that power today's scales. This will help you make better purchasing decisions for your software integration projects.

What sensors are used in scales?

Confused by sensor jargon like strain gauge or piezoelectric? Choosing the wrong type can lead to inaccurate products and unhappy customers, a risk your company can't afford.

The most common sensor is the strain gauge, used in over 70% of consumer scales for its precision and affordability. Other types include capacitive sensors, ideal for humid environments like bathrooms, and piezoelectric sensors, which excel at measuring dynamic forces.

When we build industrial weighing systems1, the sensor is the heart of the machine. The choice defines the scale's performance. For a software provider like you, knowing these differences is key to ensuring your application receives reliable data. Here's a simple breakdown of the main types we encounter.

Core Sensor Technologies

The vast majority of scales you'll work with use one of three core sensor types. Each has its own strengths.

| Sensor Type | How It Works | Key Features | Best For |

|---|---|---|---|

| Strain Gauge | Measures resistance changes in a foil as it bends under weight. | High accuracy (to 0.1g), low cost, reliable. | Home scales, kitchen scales, industrial systems. |

| Capacitive | Measures changes in capacitance as plates move closer. | Fast response, resistant to moisture. | Bathroom scales or other damp environments. |

| Piezoelectric | Generates a voltage when pressure is applied to a crystal. | Excellent for dynamic, fast-changing forces. | Measuring impact forces, not static weight. |

In my 18 years of experience, a high-quality strain gauge sensor is the most dependable choice for most applications. It delivers the perfect balance of cost and precision that our clients need for both consumer and industrial products.

How do smart scales actually work?

Ever wonder how a quick step on a scale reveals so much data? Without understanding the process, integrating this technology into your software can feel like a black box.

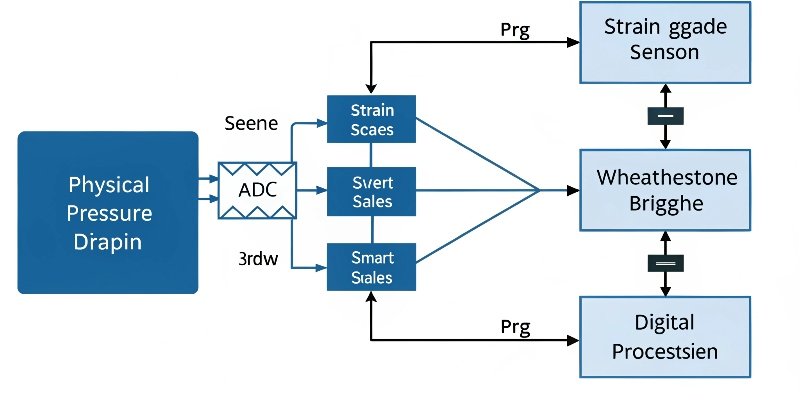

Smart scales work by converting physical pressure into a digital signal. A strain gauge sensor's resistance changes with weight, a change measured by a Wheatstone bridge. An ADC chip (like the popular HX711) digitizes this signal, which is then processed to calculate metrics.

It all starts with a simple action: placing a load on the scale. But a complex chain of events follows to turn that physical force into the numbers you see on a screen or in an app. As a technical director or purchasing manager, seeing this process clarifies how your software connects to the hardware.

From Pressure to Digital Data

- Pressure is Applied: A person or object is placed on the scale's platform. This force travels through the scale's feet.

- Sensor Bends: The force causes a tiny, imperceptible bend in an elastic metal component called a load cell2.

- Resistance Changes: A strain gauge, a foil-like resistor bonded to the load cell, is stretched or compressed. This changes its electrical resistance.

- Signal is Digitized: A specialized chip, often an Analog-to-Digital Converter (ADC)3 like the HX711, measures this tiny change in resistance. It converts the analog signal into a digital value.

- Data is Processed & Sent: A microcontroller takes this digital value, calculates the final weight, and sends it wirelessly via Bluetooth or Wi-Fi to a connected device or app.

Modern upgrades are making this process even better. We're seeing more MEMS-based sensors, which are incredibly small and often include temperature compensation4. New materials like graphene5 are also being used to reduce temperature drift, ensuring accuracy no matter the environment.

Where are the sensors on digital scales?

You know sensors are crucial, but where are they hidden? Not knowing their placement can lead to incorrect usage by the end-user, compromising the accuracy you rely on.

In most digital scales, you'll find the sensors, typically strain gauge load cells, located at the four corners of the scale. They are positioned directly above each foot. This four-point placement ensures stability and accurate weight distribution, giving a consistent reading.

The placement of sensors is not random; it's a deliberate engineering choice designed for maximum accuracy. For consumer scales6, this is especially important because users rarely stand perfectly in the center. The scale must deliver a correct reading no matter where the weight is concentrated. The four-corner design averages the pressure from all four points, which cancels out errors from off-center placement. This is the standard for almost every household bathroom or kitchen scale.

In the industrial world, things can be different. Some of our high-precision systems use a single-point load cell. These are designed for applications where the load is always placed in the same central spot, like in a production line.

Weight Sensors vs. Body Composition Sensors

It is also important not to confuse the weight sensors with the sensors used for body composition analysis.

- Weight Sensors (Load Cells): These are mechanical and hidden underneath the platform at the corners. They measure physical force.

- Body Composition Sensors (BIA Electrodes): These are the metal pads or conductive coatings you see on the top surface of a smart scale. They send a harmless, low-level electrical current through the body to measure bioelectrical impedance7, which is used to estimate body fat, water percentage, and muscle mass. Your software would receive and interpret data from both types of sensors.

Do smart scales need calibration?

Worried about your scales losing accuracy over time? Shipping a product that gives inconsistent readings can quickly destroy your brand's reputation and lead to costly returns.

Yes, all scales, including smart scales, need calibration to ensure accuracy. While high-quality scales are calibrated at the factory and are stable, factors like shipping, heavy use, or temperature changes can cause drift. Regular checks are essential for maintaining precision.

Calibration is the process of setting a scale to a known standard. Think of it like tuning a musical instrument—it needs to be done to ensure correct results. At our facility, a scale doesn't leave the factory until it passes a rigorous calibration process.

Factory Calibration vs. User Responsibility

- Our Process: Every single product we manufacture undergoes comprehensive testing. Our quality control department uses certified weights to calibrate each scale. We test its weight sensing, battery performance, and software communication. Only after passing these checks do we ship it. This guarantees that the product is perfectly accurate when your customer first opens the box.

- Why It Can Drift: Despite our best efforts, the real world can interfere. A hard drop during shipping, extreme temperature swings, or just years of heavy use can cause the sensitive internal components to drift slightly out of alignment.

- What You Can Do: We advise clients to recommend that their end-users perform simple calibration checks. This can be as easy as weighing an object with a known weight, like a dumbbell or a bag of flour. If the scale's reading is off, many models have a built-in recalibration mode that can be activated through the scale's software or app. Providing this feature in your software adds significant value and builds user trust.

Conclusion

Choosing the right smart scale means understanding its core sensors, from strain gauges to advanced MEMS. This knowledge ensures you deliver the accuracy and reliability your customers demand.

-

Explore the differences between industrial and consumer scales for better product integration. ↩

-

Understand the function of load cells in converting physical force into measurable data. ↩

-

Discover how ADCs like the HX711 digitize signals for accurate weight measurement. ↩

-

Find out how temperature compensation improves the accuracy of sensors in varying conditions. ↩

-

Discover the innovative use of graphene in sensors to enhance performance and accuracy. ↩

-

Explore the essential features of consumer scales to make informed purchasing decisions. ↩

-

Explore how bioelectrical impedance is used to assess body composition in smart scales. ↩

[…] always tell my clients that a good brand is a sign of quality, but true accuracy3 comes from the specifications you choose. A great brand can still be the wrong choice if the specs […]