Confused by all the weighbridge choices? The wrong one can be a costly mistake. Let's break down the main types to help you find the perfect fit.

Weighbridges are classified by structure (I-beam steel, concrete), installation (pit, pitless), and technology (digital, analog). You can also choose between fixed or mobile options. Your final choice depends on your specific operational needs, space, and budget.

Understanding these basic categories is the first step. But the real-world application often comes down to one key decision: the installation style1. Let's explore the most common installation types and see how they impact your day-to-day operations and long-term costs. It's a critical choice.

What is the pit type weighbridge?

Is your worksite short on space? A large, raised weighbridge can obstruct traffic. A pit-type weighbridge sits flush with the ground, saving valuable space and improving flow.

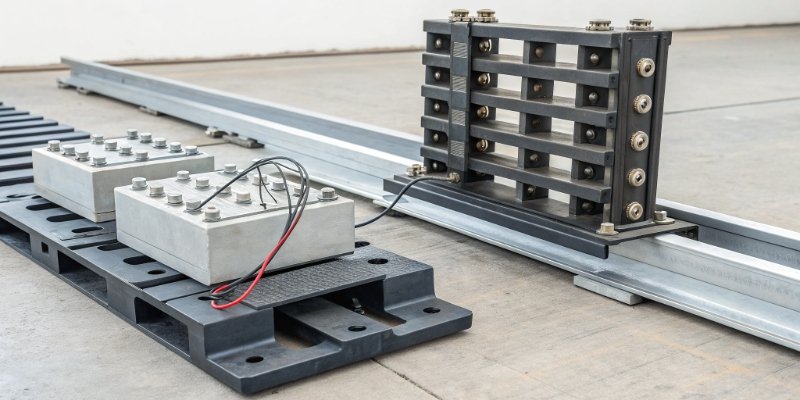

A pit-type weighbridge is installed in a concrete pit, making its platform level with the ground. This setup is ideal for sites with limited space, as it allows vehicles to drive over it from any direction and doesn't require approach ramps.

Pit weighbridges are a popular choice for a reason. Their main advantage is being unobtrusive. Because the platform is level with the ground, you don't need long entry and exit ramps. This is perfect for busy facilities or sites where space is tight. Vehicles can enter and exit from multiple angles, which improves traffic flow2.

However, there are downsides to consider. The biggest challenge is maintenance. The pit can collect water, mud, and debris. You must install a good drainage system3 to prevent sensor damage. Cleaning and servicing can also be more difficult since access is limited underneath the platform.

Advantages and Disadvantages of Pit-Type Weighbridges

| Pros | Cons |

|---|---|

| Saves significant operational space | Higher initial construction costs for the pit |

| Allows vehicle cross-traffic | Prone to debris and water accumulation |

| Aesthetically cleaner look | Requires a proper drainage system |

| No need for approach ramps | More difficult to access for cleaning/maintenance |

What is the difference between pit and pitless weighbridges?

Can't decide between a pit or pitless weighbridge? The wrong installation choice can cause major headaches. Let's compare them directly so you can see which is best.

The key difference is installation. Pit weighbridges are installed in a pit, flush with the ground. Pitless weighbridges are installed above ground on a concrete foundation, requiring ramps. Pitless is generally cheaper to install and easier to clean and maintain.

The choice between pit and pitless really comes down to your specific site and budget. From my 18 years of experience, I've seen both types work perfectly when matched to the right environment. A pitless weighbridge4 is often the default choice if you have enough space. For software vendors like you, ease of access to the load cells5 and junction box for maintenance and calibration is key. A pitless design offers superior access, which can reduce downtime. However, if your client's site is cramped, the pit design is unbeatable.

Pit vs. Pitless Weighbridge: A Detailed Breakdown

| Feature | Pit-Type Weighbridge | Pitless-Type Weighbridge |

|---|---|---|

| Space Required | Minimal; only the size of the platform. | Large; requires room for the scale and long ramps. |

| Installation Cost | High civil works cost for pit excavation. | Lower civil works cost for a simple foundation. |

| Maintenance | Difficult; confined space, requires pit cleaning. | Easy; open access to all sides and underneath. |

| Drainage | Critical; requires a dedicated drainage system. | Natural drainage; water and debris fall away easily. |

| Flexibility | Permanent installation; difficult to relocate. | Can be relocated more easily if needed. |

What are the different types of weighbridges?

Think the decision is just pit or pitless? The internal structure and sensors are just as critical. The wrong tech leads to bad data. Let's explore these other classifications.

Beyond installation, weighbridges are typed by structure (steel, concrete), portability (fixed, mobile), and electronics (analog, digital). This determines the scale's durability, accuracy, and suitability for specific jobs. For instance, a mobile weighbridge is great for temporary sites.

As a manufacturer, we build weighbridges using different core components based on the customer's needs. The choice affects everything from shipping cost to lifespan. For a software provider, the analog versus digital distinction is most important. Digital sensors offer superior accuracy, better diagnostics, and are less prone to interference. This means cleaner data for your systems. While analog systems are cost-effective upfront, digital systems often provide a lower total cost of ownership and more reliable data, which is crucial for integration. We always discuss this trade-off with our clients to find the best fit.

Weighbridge Classifications: Structure & Technology

| Category | Type 1 | Type 2 |

|---|---|---|

| Structure | I-Beam Steel: Lighter, easier to transport. | Concrete Deck: Heavy, durable, rust-resistant. |

| Portability | Fixed: Permanent for high-traffic sites. | Mobile: Can be moved between projects. |

| Sensors | Analog: Signal converted in a junction box. | Digital: Signal converted at the load cell. |

What material is used for the weighbridge platform and pit?

Worried about your weighbridge lasting? Poor materials can lead to rust, warping, and expensive downtime. Let's talk about the two main platform materials to ensure long-term durability.

The platform is usually either all-steel (using I-beams for structure) or a steel frame with a poured concrete deck. Steel is lighter and easier to install, while concrete is highly durable and resists corrosion. The pit itself is made from reinforced concrete.

The platform's material is one of the most significant choices you'll make. It directly impacts cost, shipping, installation, and lifespan. We offer both options because different environments demand different solutions. For the platform, or "deck," you have two main choices. The pit, for a pit-type installation, is always made from high-strength, reinforced concrete. This is non-negotiable. The pit must be a solid foundation that can bear the load of the scale and traffic, resist soil and water pressure, and last for decades without shifting.

Comparison of Weighbridge Deck Materials

| Feature | All-Steel Deck | Concrete Deck |

|---|---|---|

| Durability | Very strong but can rust in wet/corrosive areas. | Extremely durable, excellent corrosion resistance. |

| Installation | Faster. Arrives ready to install. | Slower. Concrete needs 2-4 weeks to cure. |

| Traction | Can be slippery; often has a diamond tread plate. | Naturally provides better traction when wet. |

| Maintenance | Requires periodic painting to prevent rust. | Virtually maintenance-free surface. |

Conclusion

Choosing a weighbridge involves balancing installation style, technology, and materials. Understanding these key differences ensures you select a reliable, cost-effective solution that perfectly fits your operational needs.

-

Understand the impact of installation style on weighbridge efficiency and maintenance. ↩

-

Understand how the right weighbridge design can enhance traffic management. ↩

-

Learn about the critical role of drainage systems in maintaining pit weighbridges. ↩

-

Discover why a pitless weighbridge might be the ideal choice for your site. ↩

-

Learn about the function of load cells in weighbridge technology and their importance. ↩

Comments (0)