Struggling with inaccurate weights from moving animals? These errors directly impact your profit and data records. Advanced weighing technology finally provides a reliable and precise solution.

To accurately weigh moving livestock, modern industrial scales use dynamic weighing systems, high-precision sensors, and intelligent software algorithms. These technologies work together to filter out motion and provide a stable, precise weight reading, turning chaos into clear data.

Getting a steady weight from a moving animal used to be a huge challenge. I remember visiting a farm where the owner was constantly guessing, leading to inconsistent feed ratios and lost income when selling. This is a common story. But technology has changed the game completely. Today, it’s not just about building a strong platform. It’s about the smart technology inside. At Weigherps, we combine robust hardware with intelligent software. This ensures you get a number you can trust every single time, which is the foundation for a modern, data-driven operation1. Let’s look at how this technology works and answers some common questions we get from clients.

How do you measure the accuracy of industrial scales?

Unsure if your scale’s readings are truly accurate? Small errors add up, costing your business money over time. You can easily verify accuracy with a few standard tests.

You measure scale accuracy using certified test weights. Key performance metrics include repeatability (consistency), linearity (accuracy across all weights), and eccentricity (accuracy on different parts of the platform). Regular calibration ensures continued precision.

When we talk about accuracy, it’s not just a single idea. It’s a combination of different performance factors. As a manufacturer for 18 years, we’ve built our quality control process around these core principles. Think of it like this: if you weigh the same object ten times, do you get the same result? That’s repeatability2. If you weigh a 10kg object and then a 100kg object, are both readings correct? That is linearity3. And if you place the weight in the corner of the scale instead of the center, does the reading change? That tests eccentricity. We test for all three before any scale leaves our factory. For our customers, especially those integrating our scales into a larger software system, knowing these details is crucial. Reliable input data is everything.

Key Metrics for Scale Accuracy

| Metric | What It Measures | Why It Matters |

|---|---|---|

| Repeatability | The scale’s ability to show the same result for the same load. | Ensures consistent and reliable measurements over time. |

| Linearity | The scale’s accuracy across its entire weighing range. | Guarantees precision for both light and heavy objects. |

| Eccentricity | The scale’s ability to show the same result regardless of load position. | Critical for weighing large or oddly shaped items, like animals that move around. |

Can livestock scales be used for other animals?

Do you need to buy a separate scale for every type of animal? That can get expensive and complicated. Your existing livestock scale might be more versatile than you realize.

Yes, a livestock scale can often weigh other animals like pigs, goats, or sheep. You must check that the scale’s capacity, platform size, and enclosure are suitable. Versatility depends entirely on its specifications, not just its name.

We often get this question from clients looking to maximize their return on investment. The answer is almost always yes, but with some planning. A scale we designed for a cattle rancher was later used for his flock of alpacas. The key was that the scale had a high enough resolution to accurately weigh the much lighter alpacas, and the pen was secure enough to hold them. The most important factors are the scale’s technical specifications. A scale built for 1500kg cattle might not be sensitive enough for 50kg sheep. Conversely, a sheep scale would be too small and not strong enough for a bull. When we provide custom solutions, we always ask about all potential uses. This allows us to recommend a scale with the right capacity, platform size4, and software settings to give you the most flexibility.

Matching the Scale to the Animal

| Animal | Average Weight Range | Recommended Platform Size | Key Considerations |

|---|---|---|---|

| Cattle | 400 – 1200 kg | 2.5m x 1m or larger | High capacity, robust cage, non-slip floor. |

| Pigs | 100 – 300 kg | 1.5m x 0.8m | Solid side panels, easy to clean. |

| Sheep/Goats | 40 – 90 kg | 1.2m x 0.5m | Lower capacity, high sensitivity, smaller pen. |

What type of weighing scale is more accurate?

Overwhelmed by the different types of scales on the market? Choosing the wrong one can lead to unreliable data. But accuracy is less about type and more about technology.

For industrial uses, electronic scales are far more accurate than old mechanical ones. They use high-quality load cells and advanced digital processors to deliver precise measurements. For moving objects, dynamic electronic scales are the most accurate.

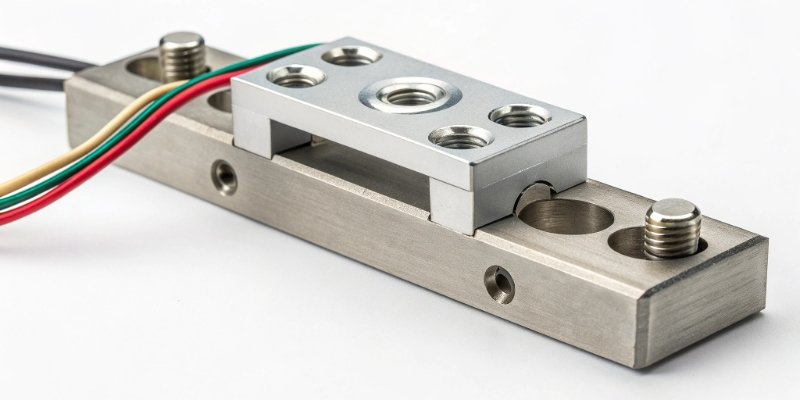

In the past, all scales were mechanical, using springs and levers. They were revolutionary for their time, but they have limits. They wear down, are sensitive to temperature, and can be difficult to read precisely. Today, everything is about electronic scales. The "heart" of an electronic scale is the load cell. It’s a sensor that converts force into a measurable electrical signal. The quality of this component is critical. At Weigherps, we use high-precision load cells5 and pair them with smart digital indicators. This doesn’t just give you a number; it gives you a piece of data. This data can be sent to a computer, stored in the cloud via IoT, and integrated into your management software. For our software vendor clients, this is the most important part. The scale becomes a data collection device that feeds their systems with accurate, real-time information.

How accurate are cattle scales?

Are you skeptical about getting a precise weight from a restless cow? This uncertainty can make you question your operational data. Modern cattle scales are incredibly accurate, even with movement.

High-quality cattle scales with dynamic weighing technology are extremely accurate, typically within ±0.5% to 1% of the animal’s true weight. This precision comes from advanced software filters that average out fluctuations caused by movement.

I understand the skepticism. Watching an animal move around on a platform and seeing the numbers jump, it’s natural to wonder how any final reading can be trusted. This is where intelligent weighing algorithms6 come in. It’s the "brain" of the scale. When you activate the animal weighing mode, the scale’s processor begins taking hundreds of readings per second. The software then uses a special filter to ignore the sudden spikes and dips from the movement. It calculates a stable average weight over a few seconds and locks it in. This is called dynamic weighing. The accuracy of ±0.5% to 1% is a game-changer. For a 500kg animal, that means the measured weight is within 2.5kg to 5kg of its actual weight. This level of precision is essential for managing feed efficiency7, monitoring health, and maximizing profit at sale. It transforms weighing from a rough estimate into a reliable management tool.

Conclusion

Modern weighing technologies, from dynamic algorithms to IoT integration, make livestock weighing precise and efficient. This empowers your business with reliable data for better growth and profitability.

-

Learn about the advantages of adopting a data-driven approach in livestock management. ↩

-

Learn why repeatability is crucial for consistent measurements in weighing systems. ↩

-

Explore how linearity affects the accuracy of measurements across different weights. ↩

-

Learn how the right platform size ensures accurate and safe weighing of animals. ↩

-

Explore the critical role of load cells in providing precise weight measurements. ↩

-

Learn how advanced algorithms enhance the precision of weight measurements. ↩

-

Understand the connection between accurate weighing and improved feed efficiency. ↩

Comments (0)