Are you struggling to choose the right load cell? Making the wrong choice can lead to inaccurate data and costly operational errors, hurting your project's success and your bottom line.

The main difference is how the weight signal is processed. An analog load cell outputs a raw, continuous voltage signal. A digital load cell has a built-in microprocessor that converts this signal into a clean, digital output right inside the sensor itself, making it more accurate.

Choosing between these two technologies can feel overwhelming. I see clients wrestle with this decision all the time. On one hand, you want the latest technology, but on the other, you need to manage costs. The truth is, the "best" option depends entirely on your specific needs. In this post, I will break down the key differences based on my 19 years in the industrial scale business. My goal is to give you the clarity you need to choose with confidence, ensuring your weighing system1 is both reliable and cost-effective2. Let’s dive in.

What is a digital load cell?

Are you getting unreliable weight data from your current system? Electrical noise and signal degradation can corrupt analog readings, causing major headaches and inaccurate results in your operations.

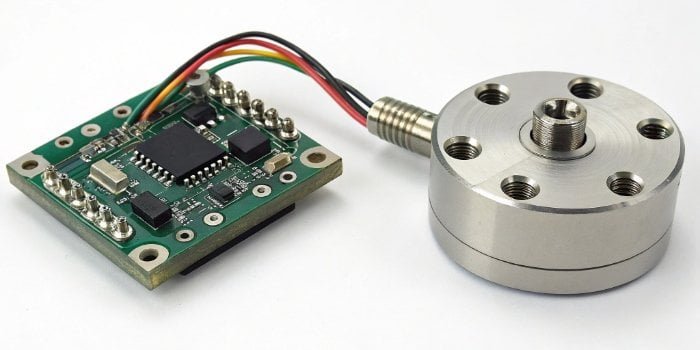

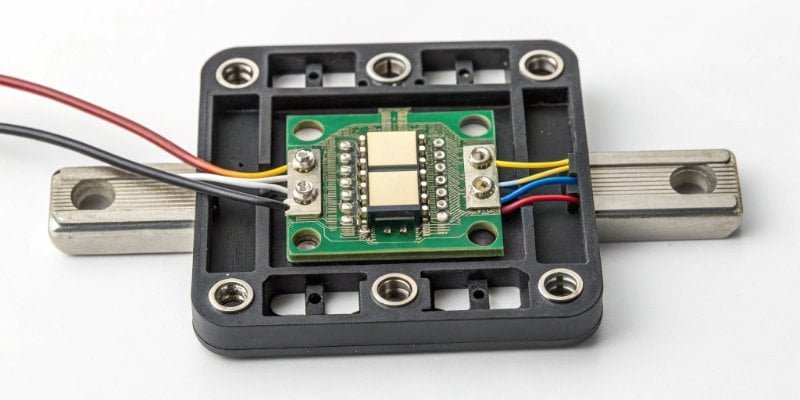

A digital load cell is a smart sensor that combines a traditional strain gauge with an internal microprocessor. This built-in chip digitizes, filters, and corrects the weight signal at the source. This ensures a highly accurate and stable output before it even leaves the cell.

I remember working with a client in the chemical industry who was experiencing fluctuating readings on their tank weighing system. The long cable runs from the analog load cell3s to the indicator were picking up electrical noise4 from nearby motors. Every time a motor started, their batch measurements5 were thrown off. We replaced their analog setup with our digital load cell6s. Because the signal was converted to a digital format inside the load cell housing, it was no longer vulnerable to interference. Their problem vanished overnight.

A digital load cell fundamentally changes the weighing process. Here's how it works:

Key Internal Components

- Strain Gauge: Just like an analog cell, this is the core sensor that physically deforms under load.

- A/D Converter7: This is the Analog-to-Digital converter. It takes the raw, weak voltage signal from the strain gauge8 and turns it into a digital value (1s and 0s).

- Microprocessor: This is the "brain" of the cell. It takes the digital signal and performs several crucial tasks like temperature compensation, linearity correction, and filtering.

This internal processing means the data you receive is already clean, stable, and ready to be used by your software or control systems.

What is the main difference between analog and digital?

Are you tired of complex calibration procedures and fighting signal interference? These common issues with traditional weighing systems can slow down your operations and compromise your data's integrity.

The main difference is where the signal is processed. Analog systems send a raw, vulnerable signal to an external indicator for processing. Digital systems process the signal internally, sending a robust, pre-calibrated digital output that is highly resistant to electrical noise and distance.

As a software vendor, the quality of the data your system receives is everything. Poor input data leads to poor output, which can damage your reputation. This is where the difference between analog and digital becomes critical. An analog signal is like a quiet whisper traveling through a noisy room; it can easily get distorted. A digital signal is like a clear, encrypted message; it arrives intact, regardless of the noise around it.

This fundamental difference has a huge impact on performance, cost, and maintenance. At Weigherps, we provide both, but we always guide our clients toward the technology that best protects their data integrity9.

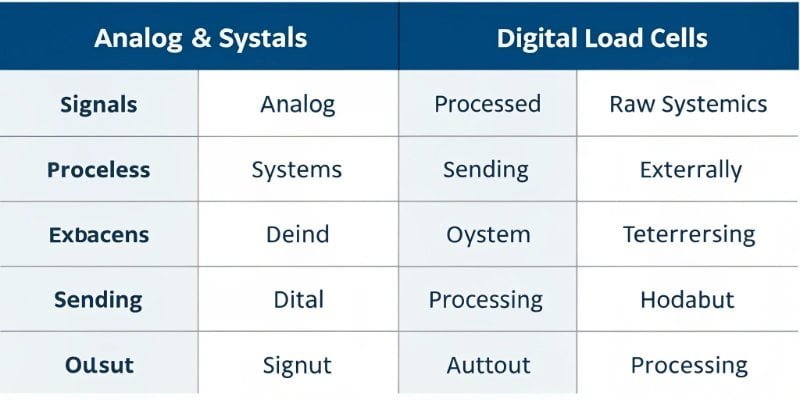

Here is a simple table to break down the key differences:

| Feature | Analog Load Cell | Digital Load Cell |

|---|---|---|

| Signal Output | Raw, continuous voltage (mV/V) | Processed digital signal (e.g., RS485) |

| Accuracy | Good, but susceptible to external factors | Higher, with internal error correction |

| Interference | Vulnerable to electrical noise and radio signals | Highly resistant to interference |

| Calibration | Complex, requires junction box and trimming pots | Simple, often done digitally via software |

| Troubleshooting | Difficult, hard to isolate a single faulty cell | Easy, each cell can be diagnosed individually |

| Cable Length | Limited, signal degrades over distance | Can support very long cable runs without loss |

| Initial Cost | Lower | Higher |

Thinking about these factors in the context of your software helps clarify the choice. If your application demands the highest data integrity, a digital system is a safer bet.

Which is better, an analog or digital weighing machine?

Choosing a complete weighing machine feels complex. You know the technology inside it will determine its performance and your return on investment. Let's make this decision easier for you.

A digital weighing machine is generally better for industrial automation, data-heavy applications, and harsh environments. It provides cleaner data, easier diagnostics, and better system integration. An analog machine is a perfectly cost-effective choice for simple, standalone weighing tasks where basic accuracy is sufficient.

The choice isn't about which technology is "better" in a vacuum; it's about which system delivers the most value for your specific job. For a software provider looking to integrate weighing data into a larger enterprise resource planning (ERP) or warehouse management system (WMS), a digital machine is almost always the superior choice. The clean, addressable data from each load cell makes integration seamless and provides a level of diagnostic insight that analog systems simply can't match.

When to Choose a Digital Weighing Machine

Choose digital when your project involves:

- High Precision Requirements: Applications like batching, filling, or formulation where small errors are very costly.

- Harsh Industrial Environments: Facilities with heavy machinery, motors, or radio transmitters that create electrical noise.

- Multi-Cell Systems: Truck scales, large hoppers, or tank farms where multiple load cells work together. Digital systems allow you to monitor the health of each cell individually.

- Need for Advanced Diagnostics: When you need to quickly identify and replace a faulty component without taking the whole system offline.

When an Analog Weighing Machine is a Good Fit

You can confidently choose analog for:

- Simple, Standalone Applications: A basic floor scale for shipping and receiving, or a simple bench scale for manual weighing.

- Cost-Sensitive Projects: When the initial purchase price is the most important factor and the environment is clean.

- Basic Weighing: If you just need a weight reading and are not integrating the data into a complex software system.

Ultimately, we help our partners analyze their total cost of ownership10. A digital machine might cost more upfront, but its reliability and low maintenance can save you much more in the long run.

Which is better, analog or digital?

Are you afraid of overspending on advanced features you don't actually need? Or worse, underspending on a critical component only to get poor, unreliable performance? This choice is vital.

"Better" depends entirely on your application. For high-precision, networked systems or in environments with electrical noise, digital is far superior. For simple, single-cell scales in controlled environments, analog provides excellent value for a lower initial cost.

In my experience, this question often comes down to balancing risk and budget. The risk of inaccurate data can be immense. For one of our clients in the food processing industry, a small error in a batch recipe could ruin thousands of dollars of product. For them, the higher cost of a digital system was a small price to pay for the insurance it provided against such errors. Conversely, a small retailer using a scale to weigh packages for shipping doesn't face the same level of risk. An analog scale works perfectly for them.

A Practical Decision Framework

To make the right choice, ask yourself these questions:

- What is the cost of an error? If inaccurate weighing leads to significant financial loss, safety risks, or product recalls, invest in digital.

- What is the operating environment like? If there are high levels of vibration, temperature fluctuation, or electrical noise, digital's built-in compensation and shielding are a major advantage.

- How critical is system uptime? Digital systems are faster to troubleshoot and repair because you can identify the exact faulty component from the indicator. This drastically reduces downtime.

- Will the system need to scale or integrate with other software? Digital systems are built for the age of IoT11 and Industry 4.0. They communicate easily with other machines and software platforms.

My insight after nearly two decades is this: Digital has become the mainstream choice for most modern industrial weighing for a reason. But in simple scenarios, analog technology is still a reliable and cost-effective workhorse.

Conclusion

Digital load cells are the top choice for precision and reliability in modern industry. However, for simple needs and tight budgets, analog systems remain a smart, cost-effective option.

-

Explore key factors to ensure your weighing system meets operational needs. ↩

-

Explore various cost-effective options for reliable and accurate weighing. ↩

-

Explore the benefits of analog load cells for simpler, cost-effective weighing solutions. ↩

-

Understanding electrical noise is crucial for maintaining accurate weight readings. ↩

-

Learn how load cells enhance accuracy in batch processing applications. ↩

-

Discover how digital load cells enhance accuracy and reliability in weight measurement. ↩

-

Learn about the A/D converter's role in transforming analog signals to digital. ↩

-

Gain insights into strain gauges, the core component of load cells, and their importance. ↩

-

Discover the significance of data integrity for reliable operations and decision-making. ↩

-

Understanding total cost of ownership helps in making informed investment decisions. ↩

-

Discover how IoT integration enhances the functionality of modern load cells. ↩

Comments (0)