Struggling with 'static' vs. 'dynamic' sensitivity? Choosing wrong means bad data and wasted costs. I'll help you understand the difference to ensure you get accurate measurements every time.

Static sensitivity is the ratio of output change to a steady input change, like a scale measuring a fixed weight. Dynamic sensitivity describes how a sensor tracks fast-changing inputs, like an accelerometer measuring vibrations, considering response time and frequency.

That's the high-level view. But as a manufacturer with 18 years of experience, I know the real value is in the details. The real-world applications are where this distinction truly matters. To make the best purchasing decisions for your software solutions, you need to go beyond the basic definitions. Let's break down what 'static' and 'dynamic' really mean in practice so you can integrate hardware successfully.

What is the difference between static and dynamic?

Do static and dynamic seem like abstract concepts? Applying them incorrectly in engineering or software development can lead to system failures or inaccurate results. Let's ground these terms with clear examples.

Static means stationary or changing very slowly, where time isn't a factor. Think of the weight of an object at rest. Dynamic means constantly changing and in motion, where time is crucial, like measuring the force of an impact as it happens.

In my 18 years of manufacturing industrial scales, I’ve seen this difference firsthand. Think about weighing a truck. When a truck stops completely on a weighbridge to get its weight, that’s a static measurement. The system has time to stabilize and give a precise, final number. But now imagine a system where trucks drive over a sensor embedded in the road without stopping. This is a dynamic measurement. The system must capture the weight in a fraction of a second as the axle passes over it. The hardware and software needs are completely different. Your software has to be ready to handle a rapid stream of data, while for static weighing, it just needs to wait for one final, stable value.

Key Differences at a Glance

| Feature | Static | Dynamic |

|---|---|---|

| Time | Independent of time or very slow | Highly dependent on time |

| State | At rest, in equilibrium | In motion, constantly changing |

| Example | A book sitting on a table | A ball bouncing |

| Goal | Measure a final, stable value | Measure how a value changes over time |

Understanding this core distinction is the first step toward choosing the right hardware for your software to interface with, preventing integration headaches down the line.

What does static sensitivity mean?

Does the term 'static sensitivity' feel too academic for your practical needs? Ignoring it could mean you're buying a sensor that isn't precise enough for stable measurements, leading to unreliable data for your software.

Static sensitivity is the ratio of output change to a stable, slow-changing input. It essentially measures a sensor's 'gain.' For a pressure sensor, it might be how many volts the output changes for every 1 Pascal of steady pressure applied.

Static sensitivity is all about precision when things are still. Imagine one of our clients who needs to monitor the grain level in a massive silo. The weight changes very slowly as the silo is filled or emptied. For their inventory management software1 to be accurate, they need a weighing system with high static sensitivity2. This means even a small change in weight results in a clear, measurable change in the electronic signal. The formula is simple: Sensitivity (K) = ΔOutput / ΔInput. A sensor with high static sensitivity gives you a larger output signal for the same input, making it easier for your system to read small changes accurately. For you as a software provider, this is critical. When your software relies on hardware for data, you must ensure the sensor's static sensitivity matches the application's required precision. Otherwise, your software might get noisy or inaccurate data, leading to faulty inventory reports or incorrect batching.

What is the difference between static and dynamic sensors?

Are you trying to decide between a static or dynamic sensor for your project? Choosing the wrong type is like using a bathroom scale to weigh a speeding bullet—it just won't work and will frustrate your development team.

Static sensors are designed for accuracy in stable conditions, often with slower response times. Dynamic sensors are built for speed and fidelity, capturing rapid changes accurately by considering things like frequency response and phase shift, which static sensors ignore.

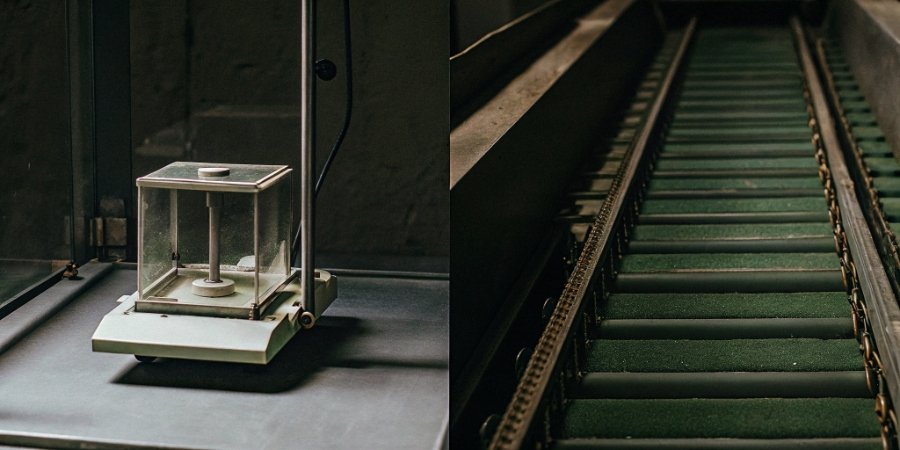

Let me give you a clear example from our production floor. We build large platform scales for weighing pallets in a warehouse. These use static sensors3 (load cells). The goal is to get a highly accurate and repeatable weight after the pallet has been placed and has settled. Speed is not the priority; accuracy is. In contrast, we also build checkweighers for food production lines. These systems use dynamic sensors4. They must weigh hundreds of packages per minute as they move along a conveyor belt. The sensor must react instantly, capture the weight, and reset for the next package in milliseconds. For you as a software vendor, the integration is completely different. The software for the static pallet scale can be simple: query the scale and get a single weight value. For the dynamic checkweigher, your software must process a high-speed data stream, filter out noise from vibrations, and make a pass/fail decision in real-time. Choosing the right sensor type from the beginning saves enormous development time and ensures your system works as intended.

Sensor Design Breakdown

| Characteristic | Static Sensor | Dynamic Sensor |

|---|---|---|

| Goal | High accuracy, stability, repeatability | High speed, fast response, fidelity to input signal |

| Application | Lab balances, silo weighing, truck scales | Checkweighers, vibration monitors, impact testers |

| Software Need | Poll for a final, stable value | Process a continuous, high-frequency data stream |

What is the difference between static and dynamic response?

Do terms like 'transient response' and 'frequency characteristics' sound overly complex? They are the key to understanding if your system can keep up with real-world changes. I'll explain it with a simple analogy.

Static response is the final, settled output a system gives after all changes have settled. Dynamic response describes the system's behavior while the input is changing, including any delay, overshoot, or oscillation before it settles.

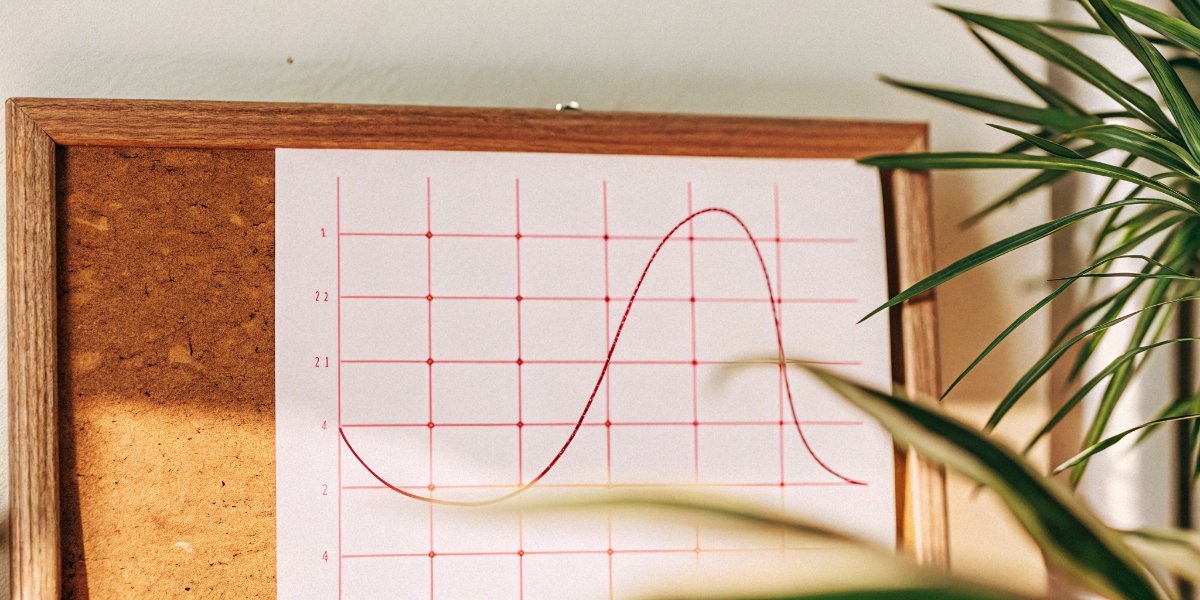

Let's go back to the scale. You place a 10 kg weight on it. After a second, the display reads exactly 10.00 kg. That final reading is the static response. But what happens in that first second? When you first place the weight, the display might quickly jump to 11 kg (overshoot5), dip down to 9.5 kg, and then settle at 10.00 kg. That entire behavior—the overshoot and settling—is the dynamic response. For you as a software provider, this is a crucial distinction. If you are developing an application for simple weighing, your software will need to wait for the dynamic response to end and only record the final, static response. You might even need to add filtering algorithms to ignore the initial fluctuations. However, if you are creating a system for shock or vibration analysis, the dynamic response is the data you want to capture. In that case, your software needs to be fast enough to record every peak and valley of the signal. Understanding the response type your application needs determines the logic you build.

Response Characteristics

| Aspect | Static Response | Dynamic Response |

|---|---|---|

| When it Occurs | After the system has stabilized | During the transition period, while the input is changing |

| What it's about | The final, correct destination | The journey to get to that destination |

| Key Metrics | Accuracy, precision, linearity | Rise time, overshoot, settling time6, frequency response7 |

Conclusion

Understanding the difference between static and dynamic is crucial. Static is for stable accuracy; dynamic is for tracking rapid changes. Choosing correctly ensures your system's data is always reliable.

-

Discover how sensor data integration enhances the accuracy of inventory management systems. ↩

-

Explore this link to understand how static sensitivity impacts sensor accuracy and data reliability. ↩

-

Discover the applications of static sensors and how they ensure accuracy in stable conditions. ↩

-

Find out how dynamic sensors work and their importance in capturing rapid changes. ↩

-

Learn about overshoot in sensor responses to better manage data accuracy. ↩

-

Understand settling time to ensure your systems provide accurate and reliable data. ↩

-

Learn about frequency response to understand how it affects sensor accuracy in dynamic situations. ↩

Comments (0)