Struggling with scale integration? Mismatched protocols create data chaos and downtime. We'll show you the essential protocols for seamless, accurate, and reliable connections in your smart factory.

For modern weighing scales, essential protocols include Modbus for industrial automation (PLC/DCS), RS-232/RS-485 for serial communication, and specialized protocols like OPC UA for secure, cross-platform data exchange. Choosing the right one ensures seamless integration with systems like MES and ERP.

Getting the right data from your scales to your systems is crucial. I've seen projects stall because of a simple protocol mismatch. But it doesn't have to be this complicated. Let's break down the most common protocols you'll encounter, so you can make informed decisions for your software and a smooth integration for your clients.

Which protocol is commonly used for communication?

Overwhelmed by protocol options for your weighing systems? Choosing the wrong one can cause major integration problems. For most industrial applications, Modbus is the go-to standard for a reason.

Modbus is the most commonly used communication protocol in industrial environments. Its simplicity, open standard, and robust performance make it ideal for connecting weighing scales to PLCs, HMIs, and SCADA systems, ensuring reliable data transfer for process control and monitoring.

Modbus1 has been the workhorse of industrial automation2 for almost as long as we've been in business, and for good reason. Its master-slave architecture is very straightforward. One device, the master like a PLC3, requests information from other devices, the slaves, like our weighing scales. This simplicity makes it incredibly reliable and easy to troubleshoot when issues arise. As a software provider, supporting it is non-negotiable for industrial applications.

Key Modbus Variants

You will mainly deal with two versions of Modbus. Modbus RTU is used on serial lines like RS-4854. Modbus TCP/IP uses standard Ethernet5 networks. Your software should support both to give your clients maximum flexibility. It means your solution can connect to older, existing equipment and the newest factory networks without any issue.

| Feature | Modbus RTU | Modbus TCP/IP |

|---|---|---|

| Physical Layer | Serial (RS-2326, RS-485) | Ethernet |

| Speed | Slower | Faster |

| Best For | Local device connections | Network-wide communication |

| Complexity | Simpler implementation | More complex, uses IP stacks |

We ensure our scales support both. This allows our clients to integrate them into any factory environment, new or old, providing the flexibility your software needs to be a truly universal solution.

How are weighing scales connected to PLC?

Trying to link a scale directly to a PLC? Incorrect wiring or protocol settings can halt your entire automation process. We make this connection straightforward using proven industrial standards.

Weighing scales are typically connected to a PLC using either a serial connection (RS-232/RS-485) running a protocol like Modbus RTU, or an Ethernet connection using Modbus TCP/IP, PROFINET, or EtherNet/IP. The choice depends on the PLC brand, distance, and required data speed.

Connecting our scales to a PLC is a core part of what we do every day. The best method depends on the customer's factory setup, but it usually comes down to two main options: a serial connection or an Ethernet connection.

The Serial Connection Path

For many factories, a serial connection using RS-485 is a perfect choice. It is very cost-effective and extremely robust against electrical noise on the factory floor. This method lets you connect multiple scales to a single PLC port, even over long distances. This is great for large production lines. The data is often transmitted using the Modbus RTU protocol we just discussed. From a software perspective, this means your application needs a solid serial communication library to parse the data packets correctly.

The Ethernet Connection Path

For more modern factories running Industry 4.0 initiatives, Ethernet is the way to go. Protocols like Modbus TCP/IP, PROFINET7 (for Siemens PLCs), and EtherNet/IP8 (for Rockwell/Allen-Bradley PLCs) run over standard network cables. This gives you higher speeds, easier integration with company IT networks, and the ability to monitor scales remotely. I remember a project with a software vendor whose client used Siemens PLCs. We provided our scales with a PROFINET interface, and their software could immediately pull weight data for their MES9 system. That seamless compatibility is what we strive to provide.

Which protocol is commonly used for asynchronous serial communication?

Need simple, direct communication with a scale? Asynchronous serial is the answer, but one wrong setting leads to gibberish data. RS-232 remains the most common and reliable protocol for this.

RS-232 is the most widely used protocol for point-to-point asynchronous serial communication. It's perfect for connecting a weighing scale directly to a PC, printer, or older terminal for simple data output, though it is limited by short cable lengths.

When you just need a simple, direct link between a scale and one other device, asynchronous serial communication10 is the classic solution. The best-known protocol here is RS-232. The term "asynchronous" just means the two devices do not share a timing clock signal. Instead, they must agree on the timing rules before they start talking.

Matching the Settings is Key

For communication to work, both the scale and the connected device must use the exact same settings. A mismatch here is the number one cause of support calls and frustration. I learned this the hard way early in my career, spending a full day troubleshooting what turned out to be a simple parity mismatch.

| Parameter | Common Settings | Description |

|---|---|---|

| Baud Rate | 9600, 19200, 38400 | The speed of data transfer. It must match. |

| Data Bits | 7 or 8 | The number of bits in each data character. |

| Parity | None, Even, Odd | A simple form of error checking. |

| Stop Bits | 1 or 2 | Bits that signal the end of a character. |

As a software provider, giving your users an easy-to-use configuration screen for these settings is crucial. While RS-232 is limited to short distances of about 15 meters, its simplicity makes it perfect for connecting to a nearby label printer or a local PC for direct data capture. For anything longer, we always recommend RS-485.

What is the digital communication protocol used in instrumentation?

Integrating diverse instruments from multiple vendors is a headache. Proprietary protocols create data silos and compatibility nightmares. A universal digital protocol like OPC UA simplifies everything.

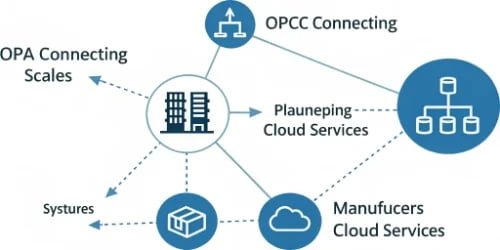

OPC UA (Open Platform Communications Unified Architecture) is a leading digital communication protocol for instrumentation. It provides a secure, platform-independent framework for data exchange, allowing weighing scales to communicate seamlessly with MES, ERP, and cloud systems across different manufacturers.

In the world of modern instrumentation and Industry 4.0, the protocol everyone is talking about is OPC UA11. It is much more than just a communication protocol. It is a complete framework for interoperability. It was designed from the ground up to solve the problem of getting devices from different manufacturers to talk to each other securely and efficiently.

Why OPC UA is a Game-Changer

Unlike older protocols that just send raw numbers, OPC UA provides context. A scale doesn’t just send the number "10.5". It sends a message saying, "The current weight is 10.5 kilograms, measured at this specific time, from this specific device." This feature is called information modeling12, and it is incredibly powerful. For you as a software vendor, this means less time trying to understand cryptic data streams and more time building great features for your customers. Additionally, OPC UA is platform-independent and has strong security built right into the standard.

We see OPC UA as essential for the future of our industry. It allows our scales to connect directly and securely to MES, SCADA, and even cloud-based AI platforms. This enables the kind of smart manufacturing13 and predictive maintenance14 that our most advanced clients are demanding now.

Conclusion

Mastering protocols like Modbus, RS-232, and OPC UA is key. It ensures your weighing scales integrate seamlessly, providing reliable data for any modern industrial or software application.

-

Explore this link to understand why Modbus is the go-to protocol for reliable industrial communication. ↩

-

Learn about the benefits of industrial automation and its impact on modern manufacturing. ↩

-

Understand the role of PLCs in automation and their connection with weighing systems. ↩

-

Discover how RS-485 enhances communication reliability over long distances in industrial settings. ↩

-

Explore the advantages of using Ethernet for faster and more reliable industrial communication. ↩

-

Learn about RS-232's role in connecting devices and its advantages in simple data transfer. ↩

-

Learn about PROFINET's role in connecting devices in Siemens PLC environments. ↩

-

Discover how EtherNet/IP enhances connectivity and data exchange in industrial applications. ↩

-

Learn how MES systems utilize data from weighing scales for efficient manufacturing processes. ↩

-

Understand the principles of asynchronous communication and its applications in data transfer. ↩

-

Find out how OPC UA facilitates seamless communication across different platforms and devices. ↩

-

Discover how information modeling enhances data context and usability in industrial applications. ↩

-

Explore the concept of smart manufacturing and its reliance on advanced communication protocols. ↩

-

Learn how accurate data can enhance predictive maintenance strategies in manufacturing. ↩

Comments (0)