Are you losing time and money to slow, manual weighing processes? This inefficiency creates bottlenecks, introduces errors, and hurts your bottom line, but there is a fast, automated solution.

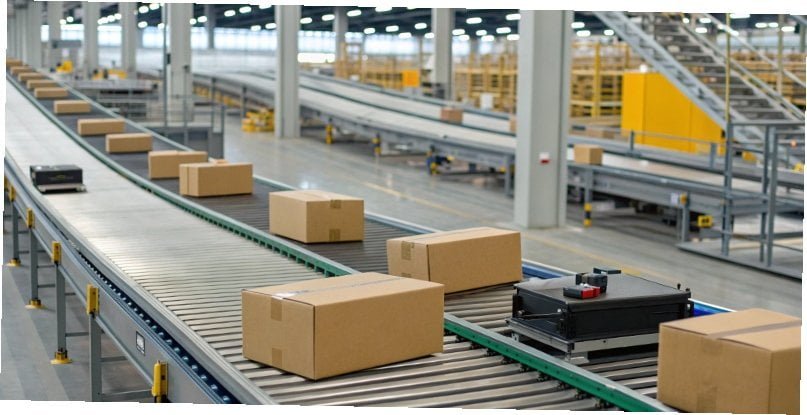

Dynamic weighing is essential for any industry that needs to measure the weight of objects in-motion, quickly and continuously. Logistics, food and beverage, pharmaceutical, chemical, and manufacturing companies all rely on it to streamline operations, ensure quality control, and maintain production efficiency without stopping the line.

You might be surprised by how many sectors depend on this technology to stay competitive. It's not just about speed; it's about accuracy, data, and complete process control1. Let's explore which industries gain the most and why this technology has become so critical for their success.

What industries benefit most from in-motion weighing?

Does your production line suffer from bottlenecks caused by static weighing? These pauses slow down your entire operation, reduce output, and directly impact your ability to meet demand.

Logistics, food, pharmaceutical, and manufacturing industries benefit the most from in-motion weighing. They use it for everything from package sorting and quality control to ensuring product weight compliance. This technology seamlessly integrates into their lines, streamlining operations and boosting overall productivity.

In my 18 years of experience, I've seen firsthand how transformative dynamic weighing can be across different sectors. The core advantage is replacing a stop-and-go process with a continuous flow. This is crucial for high-volume operations where every second counts. For example, an express delivery company can’t afford to stop every package to weigh it. Similarly, a food processing plant producing thousands of snacks a minute needs to check weights without halting production. In industries like pharmaceutical2s, dose accuracy is a matter of safety, and dynamic weighing provides that high-precision check at speed. It's a foundational technology for modern automation.

| Industry | Primary Benefit | Common Application |

|---|---|---|

| Logistics & Express | Speed & Efficiency | Automatically weighing and sorting thousands of parcels per hour for accurate shipping fees3 and routing. |

| Food & Beverage | Quality & Compliance | Verifying that every bag of chips or bottle of soda meets the labeled net weight. |

| Pharmaceuticals | Safety & Precision | Ensuring exact dosages in pill packets or vials, rejecting any that are off-weight. |

| Manufacturing | Quality Control | Checking kits for missing components or verifying the weight of finished electronic goods. |

How does dynamic weighing improve production line efficiency?

Do constant pauses for manual checks hold up your production line? These delays are not just annoying; they are costly, reduce your total throughput, and limit your growth potential.

Dynamic weighing removes the need to stop items for measurement. It integrates directly into conveyor systems, weighing products as they move. This full automation increases throughput, reduces labor costs, provides real-time data for process control, and eliminates production bottlenecks.

The primary way dynamic weighing boosts efficiency is by creating an uninterrupted flow. A traditional static scale forces you to stop an item, weigh it, and then move it again. A dynamic scale weighs it in the few seconds it takes to pass over the scale section of the conveyor. As a manufacturer, we've helped clients who saw their sorting efficiency in logistics centers jump by over 30% after installation. This improvement comes from several factors.

Automation and Labor Savings

You no longer need an employee dedicated to weighing products. The system handles it automatically. This not only cuts labor costs but also significantly reduces the chance of human error.

Real-Time Process Feedback

The scales send weight data directly to your factory's management system. If a filling machine starts putting too much powder in a bag, the system flags it instantly. You can make adjustments immediately, not after an entire batch is ruined. This proactive control saves immense material costs and prevents rework.

What are the most common applications of checkweighers in manufacturing?

Are you worried about inconsistent product quality or shipping incomplete orders? Sending out underweight products damages your brand's reputation, while overweight items waste valuable materials and cut into profits.

The most common applications are verifying package contents to ensure they are complete, ensuring compliance with net weight regulations, and identifying production line issues. They are essential in food, pharmaceutical, and consumer goods manufacturing for 100% weight inspection and quality assurance.

A checkweigher4 is a specific type of dynamic scale that acts as a gatekeeper on the production line. Its job is simple: weigh every single product that passes over it and use that data to make a decision. At our company, we design these systems to be incredibly precise, even for tiny items like electronic components or cosmetic products. They are fundamental for robust quality control5.

Ensuring Legal and Commercial Compliance

Many products are sold by weight, and there are strict laws governing this. A checkweigher ensures every package leaving your factory is within the legal tolerance, protecting you from fines and helping you maintain fair trade practices.

Verifying Product Completeness

Imagine selling a kit with ten small parts. A checkweigher can confirm all ten parts are in the box just by its weight. If a box is too light, the system automatically rejects it before it gets shipped to a customer. This is common in electronics and auto parts manufacturing6.

Optimizing Production Filling Processes

The data from a checkweigher is a powerful tool. If you see that product weights are slowly trending downwards, it's a clear signal that your filling machine needs to be recalibrated. This feedback loop helps you minimize product giveaway and maximize yield.

How is dynamic weighing used in the logistics and shipping industry?

Do you lose money because of inaccurate shipping charges from your carriers? Manually weighing millions of packages is incredibly slow, expensive, and filled with errors that directly impact revenue.

It is used to automatically weigh packages on high-speed conveyor belts to calculate shipping fees. It often works with dimensioners to determine billable weight and automatically sorts packages for routing, which dramatically increases the speed and accuracy of sorting centers.

In the logistics industry, dynamic weighing is all about revenue protection and operational speed. Every major carrier like SF Express or JD Logistics relies on it. When a package enters a sorting hub, it travels along a conveyor belt where it passes through a dynamic weighing and scanning station. The scale captures the actual weight, while a scanner captures the dimensions. This is critical for calculating what is known as "dimensional weight7" or DIM weight.

Shipping costs are based on whichever is greater: the actual weight or the DIM weight. Without an automated system to capture both, shippers often lose money on large, lightweight packages. Our dynamic weighing systems integrate seamlessly with scanners to provide this crucial data for every single package, ensuring accurate billing.

Beyond billing, the weight data is used for automated sorting. Once a package is weighed, the system knows how to route it. A heavy package might be diverted to a specific conveyor designed to handle more weight, while others are sorted by destination. This automation is what allows a modern facility to process hundreds of thousands of packages per day.

Conclusion

In short, dynamic weighing is vital for efficiency and quality control in logistics, food, and manufacturing. It transforms weighing from a bottleneck into a seamless, automated process that fuels growth.

-

Discover how dynamic weighing provides critical data for better process control. ↩

-

Understand the importance of dynamic weighing for safety and precision in pharmaceuticals. ↩

-

Discover how dynamic weighing can help accurately calculate shipping fees and reduce costs. ↩

-

Find out how checkweighers ensure product quality and compliance in various industries. ↩

-

Learn effective quality control strategies that leverage dynamic weighing technology. ↩

-

Explore how dynamic weighing enhances quality control and efficiency in manufacturing. ↩

-

Learn about dimensional weight and its impact on shipping costs and logistics. ↩

Comments (0)