Choosing a lab balance feels complicated. The wrong choice can ruin your experiments and waste money. Understanding key differences makes the decision simple and ensures you get the right tool.

To choose the right laboratory balance, you must first define your needs. A precision balance is for general weighing, an analytical balance is for sensitive quantitative analysis, and a microbalance is for extremely small, high-precision measurements. Your specific application determines the best choice.

Making the right choice for your lab is crucial. It’s not just about buying a piece of equipment; it’s about guaranteeing the accuracy and reliability of your work. Over my 18 years in the weighing industry, I’ve seen many labs struggle with this decision. They either overspend on a balance that’s too sensitive for their needs or, worse, they get inaccurate results from a balance that isn’t precise enough. The key isn’t to find the "best" balance, but to find the right balance for your specific tasks. Let’s break down how you can confidently make that choice.

Which type of balance is most accurate for laboratory use?

You need the absolute highest accuracy for your results. A tiny error can invalidate your entire research project. Microbalances offer the ultimate accuracy for your most sensitive measurements.

Microbalances are the most accurate type of laboratory balance, with readability down to the microgram (0.000001 g). Analytical balances follow, with readability to 0.1 milligrams. Accuracy is relative, so you must match the balance’s capability to your experiment’s tolerance requirements.

When we talk about accuracy in the lab, it’s important to understand a few key terms. It’s not just about one number. In my experience, clients often confuse readability1 with overall accuracy.

Understanding Key Performance Metrics

- Readability: This is the smallest division a balance can display. For a microbalance2, this could be 0.001 mg (1 µg).

- Repeatability: This measures how consistent the results are when you weigh the same object multiple times. A truly accurate balance will give you almost the exact same reading every time.

- Linearity: This refers to the balance’s accuracy across its entire weighing range.

The most accurate balance is the one that meets your specific tolerance. For weighing coatings3 on medical stents, a microbalance is necessary. For preparing a chemical standard, an analytical balance4 is usually sufficient.

| Balance Type | Typical Readability | Best For |

|---|---|---|

| Microbalance | 0.001 mg (1 µg) | Weighing extremely small samples; filter weighing |

| Analytical Balance | 0.1 mg – 0.01 mg | Quantitative analysis; standards preparation |

| Precision Balance | 1 g – 0.001 g | General lab work; buffer solutions; quality control |

Ultimately, a microbalance offers the highest level of precision, but it comes at a higher cost and requires a strictly controlled environment.

Which type of balance is used in a laboratory?

Equipping a new lab can be overwhelming. You might be wondering which balance is the standard for general lab work. Most labs use a combination, but analytical and precision balances are the workhorses.

Laboratories almost always use precision balances for general tasks like preparing buffer solutions and analytical balances for more sensitive work like quantitative analysis. Specialized labs use microbalances for high-precision tasks like particulate matter analysis or stent coating measurement.

In the labs I’ve helped equip, there’s rarely a one-size-fits-all solution. Most facilities benefit from having at least two different types of balances to cover a range of applications efficiently and cost-effectively. You wouldn’t use a highly sensitive and expensive microbalance to weigh out 100 grams of a common reagent.

Common Applications for Each Balance

-

Precision Balances: We see these everywhere. They are the go-to for preparing larger-volume solutions, general quality control checks, and weighing materials where a readability of 0.1 g to 0.001 g is perfectly acceptable. They are robust and can handle higher capacities, often up to several kilograms.

-

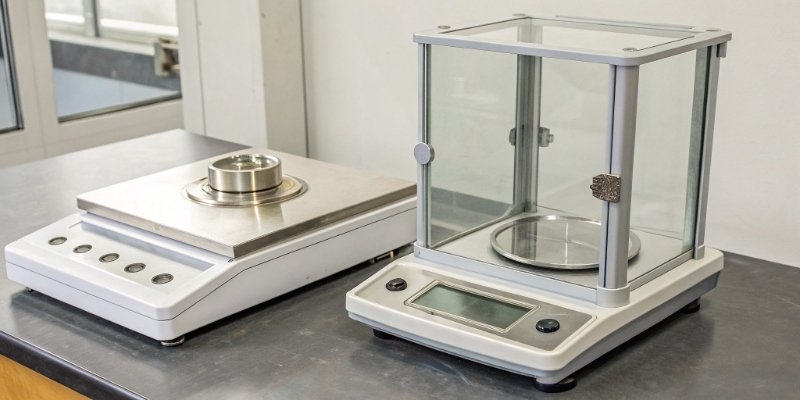

Analytical Balances: These are essential for any kind of quantitative chemical analysis. When a client needs to prepare a standard solution with a precise concentration or perform gravimetric analysis, the analytical balance is the tool. Their enclosed weighing chamber (draft shield5) protects the sensitive measurement from air currents.

-

Microbalances: These are reserved for tasks requiring the highest degree of precision on very small samples. I’ve supplied these to clients in pharmaceutical R&D for weighing active ingredients or in environmental testing6 for measuring pollutants on a filter.

A well-rounded lab typically has a precision balance7 for heavy lifting and an analytical balance for the fine-detail work.

What is the difference between analytical balance and microbalance?

They might look similar, but their functions are worlds apart. Choosing the wrong one can mean overspending for precision you don’t need or getting data that isn’t precise enough for your work.

The primary difference is their readability and sensitivity. An analytical balance typically measures to 0.1 milligrams (0.0001 g), while a microbalance measures down to one microgram (0.000001 g). This makes microbalances ideal for extremely small samples but also far more sensitive to environmental disturbances.

I often explain the difference to clients using an analogy: an analytical balance is like a high-quality photo camera, capturing fine detail. A microbalance is like a microscope, revealing a level of detail that is otherwise invisible. Both are useful, but for entirely different purposes. Their structural differences and ideal use cases highlight this. For example, a microbalance often has a second inner draft shield to provide extra protection from air currents, which can easily affect its measurements.

Let’s compare them side-by-side:

| Feature | Analytical Balance | Microbalance |

|---|---|---|

| Typical Readability | 0.1 mg to 0.01 mg | 0.001 mg (1 µg) or better |

| Typical Capacity | 50 g to 500 g | 1 g to 10 g |

| Draft Shield | Standard single enclosure | Often a double enclosure |

| Common Uses | Preparing standards, density determination | Filter weighing, pipette calibration, stent coatings |

| Environmental Needs | Requires stable surface, minimal air | Requires anti-vibration table8, temp/humidity control |

As a manufacturer, we build these balances to meet very different tolerances. The technology inside a microbalance is significantly more complex to achieve that 100-fold increase in sensitivity, which is reflected in its cost and environmental requirements.

How does one select which type of balance to use in an experiment?

You’re facing a new experiment and are unsure which balance to use. Picking the wrong tool for the job can compromise your results before you even start. A simple checklist of your needs will guide you to a perfect choice.

To select a balance, first define your required capacity (the heaviest weight) and readability (the desired precision). Then, assess your laboratory environment to see if you need special features like waterproofing or corrosion resistance. This clarifies which type of balance is the most cost-effective choice.

My core philosophy, which has served our clients well for 18 years, is that the choice must start with your own requirements. Don’t get distracted by features you’ll never use. Instead, walk through a simple decision process.

1. Define Your Weighing Requirements

First, answer these two critical questions about your sample.

- Capacity: What is the heaviest sample you will need to weigh, including the container (tare weight)? Always choose a balance with a capacity slightly higher than your maximum expected weight.

- Readability: What is the smallest increment of weight that matters for your results? This is your required readability. For example, if you need to be accurate to the fourth decimal place (0.0001 g), you need an analytical balance.

2. Assess Your Laboratory Environment

Next, look at the workspace.

- Stability: Is the bench free from vibrations? Are there strong air currents from vents or doors? More sensitive balances require more stable environments.

- Special Conditions: Will you be weighing wet or corrosive materials? If so, you may need a balance with a high IP rating9 for water resistance or one made from corrosion-resistant materials. For certain chemical environments, an explosion-proof model10 might be required for safety.

Once you have clear answers to these questions, you have a detailed profile of the balance you need. With this information, you can approach a reputable manufacturer to find a model that meets your needs without overpaying. This is how you find a truly cost-effective and reliable weighing solution.

Conclusion

Choosing the right lab balance starts with your specific needs for capacity, readability, and environment. A clear understanding of these factors ensures you find a cost-effective and reliable weighing partner.

-

Understanding readability is key to selecting the right balance for your specific needs. ↩

-

Find out why microbalances are essential for high-precision measurements in sensitive experiments. ↩

-

Discover the techniques used for weighing coatings, crucial for medical applications. ↩

-

Discover the unique features of analytical balances and their critical role in quantitative analysis. ↩

-

Learn how draft shields protect sensitive measurements from environmental disturbances. ↩

-

Explore the role of balances in environmental testing for accurate pollutant measurement. ↩

-

Learn about precision balances and their importance in general lab work and quality control. ↩

-

Discover the importance of stability in weighing and how anti-vibration tables help. ↩

-

Understand the significance of IP ratings for ensuring equipment durability in harsh conditions. ↩

-

Learn about safety features in balances designed for hazardous environments. ↩

Comments (0)