Inconsistent scale readings with temperature shifts are frustrating. This inaccuracy costs time and money. Understanding the cause is the key to a reliable solution for your business.

Temperature fluctuations cause the metal and electronic components within your scale's load cell to expand or contract. This physical change alters the electrical signals that determine weight, leading to inaccurate readings. High-precision scales require temperature compensation to remain accurate across different environments.

You now know the main reason for these frustrating inaccuracies. But this is just the beginning. To truly master your weighing processes and protect your profits, you need to understand the details. Let's break down exactly how deep this problem goes and what you can do about it. We have been helping businesses solve these issues for 18 years, and we have learned a lot.

Does temperature affect scale accuracy?

Worried that your scale's accuracy is a myth? Environmental changes can secretly sabotage your measurements. We will show you how temperature is the main culprit behind these hidden errors.

Yes, temperature directly affects scale accuracy. Both high and low temperatures alter the physical properties of the load cell's strain gauges. This can cause 'span drift' or 'zero drift,' leading to consistently incorrect measurements if not properly compensated for in the scale's design.

I remember talking to a client who operated a food processing facility. Their warehouse temperature would swing wildly from morning to night. Their old scales gave them so many problems, leading to inconsistent batch sizes. The problem lies deep within the core component of the scale: the load cell1. It's a precise piece of engineering that relies on consistency. When temperature changes, that consistency is lost. We build our scales with this reality in mind, because we know your production environment is not always a perfect laboratory.

The Science Behind Temperature Drift

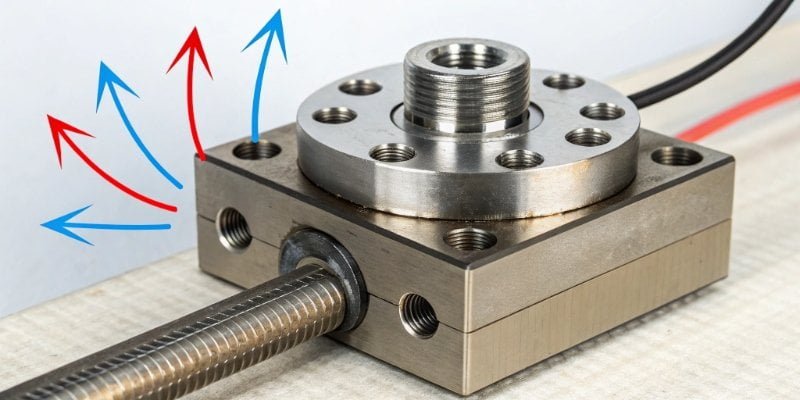

The load cell is essentially a metal structure with tiny electronic components called strain gauges attached to it. When you place a weight on the scale, the metal structure bends ever so slightly. This stretching or compressing changes the electrical resistance of the strain gauges. The scale's processor reads this change in resistance and converts it into a weight reading. However, metal expands when it gets hot and contracts when it gets cold. These physical changes also alter the strain gauges' resistance, tricking the scale into thinking the weight has changed, even when it has not.

Types of Temperature-Related Errors

This effect creates two main types of errors. A quality manufacturer works to eliminate both.

| Error Type | Description | Impact on You |

|---|---|---|

| Zero Drift | The scale shows a weight reading even when the platform is empty. | Every measurement you take will be wrong by a fixed amount. |

| Span Drift | The scale's sensitivity changes, making errors larger as the weight increases. | A 100 kg item might be off by 1 kg, while a 500 kg item is off by 5 kg. |

How accurate are industrial weighing scales?

Do you even know the real accuracy of your scales? Assuming they are 'accurate enough' can lead to major production errors. Let’s define what true industrial accuracy means for your business.

The accuracy of an industrial scale depends on its class, capacity, and design. High-precision scales can be accurate to within fractions of a gram. Accuracy is typically defined by readability, repeatability, and linearity, and is certified by organizations like OIML or NTEP.

As a manufacturer, the word "accuracy" is something we live and breathe. It is not just one thing; it is a combination of several performance factors. Customers often ask me, "How accurate is this scale?" My answer always starts with another question: "What do you need to achieve?" A scale for weighing bulk raw materials has different accuracy needs than one for mixing sensitive chemical formulas. Understanding the language of accuracy is the first step for a purchasing manager or technical director to select the right tool for the job. It helps you avoid overpaying for precision you don't need or, worse, buying a scale that isn't good enough.

Understanding Key Accuracy Metrics

To choose the right scale, you need to understand these three terms. They tell the complete story of a scale's performance.

| Term | Definition | Why It Matters for You |

|---|---|---|

| Readability | The smallest division the scale can display (e.g., 0.1 kg). | This is not accuracy itself, but it limits the precision you can see. |

| Repeatability | The ability to show the same result for the same weight every time. | This shows the scale's consistency and reliability for your process. |

| Linearity | How accurate the scale is across its entire weighing range. | This ensures it is just as accurate for light loads as for heavy ones. |

Accuracy Classes and Certifications

To make things easier, international standards organizations have created accuracy classes. For example, the OIML2 (International Organization of Legal Metrology) classifies scales, with Class III being a common standard for general industrial and commercial use. When you see that a scale, like ours, complies with international certifications such as CE, it's not just a logo. It's our promise to you that the product meets high standards for safety, health, and environmental protection, which includes reliable and accurate performance.

How to calibrate an industrial weighing scale?

Is your scale lying to you? An uncalibrated scale is just a guesser. Neglecting calibration can lead to compliance failures, wasted materials, and unhappy customers. Let's fix this now.

To calibrate an industrial scale, you first enter its calibration mode. Then, place certified test weights on the platform and follow the on-screen prompts to adjust the scale's internal settings. This ensures the displayed weight matches the actual, true weight.

Calibration is one of the most overlooked parts of scale ownership. Many users assume the scale is accurate forever right out of the box. But in my 18 years of experience, I've seen that consistent calibration3 is the single biggest factor separating reliable operations from chaotic ones. It is like tuning a musical instrument; over time, with use and environmental changes, it can drift out of tune. Regular calibration brings it back to perfect pitch. It is a simple process that anyone can learn, and it is absolutely essential for any business that relies on accurate weight measurements for its quality control4 and profitability.

A Simple Calibration Guide

Most modern digital scales make calibration straightforward. While you should always follow your specific model's manual, the general steps are almost always the same.

- Prepare the Scale: Turn it on and let it warm up for about 30 minutes. Make sure it is on a solid, level surface and that the platform is clean and empty.

- Enter Calibration Mode: This is usually done by holding down a button during startup or through a menu setting.

- Zero the Scale: The scale will first establish a true zero point.

- Apply Test Weights: The display will then prompt you to place a specific amount of weight on the platform. You must use certified, known test weights for this step.

- Confirm and Save: Once the scale registers the test weight, it adjusts its internal span settings. You then remove the weight and the scale returns to normal weighing mode, now fully calibrated.

How Often Should You Calibrate?

The right schedule depends on your specific needs, but here is a good starting point.

| Usage Frequency | Recommended Calibration Schedule |

|---|---|

| High / Critical Use | Daily or Weekly |

| Moderate Use | Monthly or Quarterly |

| Low / Non-Critical Use | Annually |

Remember, you should always recalibrate your scale if you move it, if it has received a physical shock, or after extreme temperature changes.

Why do my electronic scales give different readings?

Getting different readings for the same item is maddening. This inconsistency can make you doubt your entire production process. We will reveal the common reasons behind this frustrating problem.

Scales give different readings due to several factors. These include temperature changes, an unlevel surface, air drafts, vibrations, or internal electronic noise. Regular calibration and a stable operating environment are essential for consistent, repeatable results.

Inconsistent readings are a top complaint we hear from users of other brands. I once visited a client whose bagging scale was giving different weights for every bag, causing chaos. We looked at everything. The calibration was fine. The temperature was stable. Finally, I noticed a large industrial fan on the ceiling nearby. It was creating vibrations through the floor and subtle air drafts. We moved the scale to a more stable corner of the room, and the problem vanished instantly. It is often these simple, external factors that are the root cause. A great scale is important, but a great weighing process also requires a suitable environment.

Environmental Factors to Check

Before you blame the scale, look at its surroundings. Your scale is a sensitive instrument, and it can be affected by many things in a busy industrial setting.

- Unlevel Surface: If the scale is not perfectly level, the load is not distributed evenly across the load cells, which will cause errors. Use a spirit level to check.

- Vibrations: Is the scale near heavy machinery, conveyors, or forklifts? Even small, constant vibrations can interfere with a sensitive load cell.

- Air Drafts: For high-precision scales, open doors, windows, and even HVAC systems can create enough air movement to alter the readings.

Internal and Operational Issues

If the environment is fine, the issue may be with the scale itself or how it is being used.

| Problem | Possible Cause | Solution |

|---|---|---|

| Inconsistent Readings | Needs calibration | Perform a full calibration with certified test weights5. |

| Drifting Numbers | Static electricity / RF interference | Use anti-static mats; move scale away from other electronics. |

| Random, Large Errors | Damaged load cell or dirty parts | Clean any debris under the platform; contact technical support. |

Conclusion

Temperature, environment, and regular calibration are critical for scale accuracy. Control these factors to ensure reliable weighing, protect your process, and achieve consistent results for your business.

-

Learn about load cells to understand their crucial role in scale accuracy and performance. ↩

-

Learn about OIML certification to ensure your scales meet international accuracy standards. ↩

-

Follow this guide to calibrate your scales and maintain their accuracy over time. ↩

-

Explore the relationship between scale accuracy and effective quality control processes. ↩

-

Understanding certified test weights is crucial for accurate scale calibration. ↩

Comments (0)