Are you wondering why some scales have a glass top? It seems like a strange choice for something you stand on or place heavy items on. You might worry it’s just for looks and not very practical.

Glass is used for scales because its smooth, non-porous surface is easy to clean and resists corrosion from chemicals. Its uniform density and rigidity also provide a stable, flat platform, which is critical for high-precision weighing in labs, kitchens, and certain industrial environments.

I've been in the scale manufacturing business for nearly two decades, and the question of materials comes up all the time. People often see glass and think "fragile" or "design-focused." While glass scales do look great, the real reasons for choosing glass are highly technical and practical. It’s a material that solves specific problems that other materials, like plastic or even stainless steel, can't handle as effectively. The story of glass in weighing is one of precision, hygiene, and chemical resilience1. Let's dive into why this material is so much more than just a pretty face.

Are glass scales better?

Choosing the right scale material can be tough. You want something that's durable and will last, but you also need accurate measurements. Is glass a better overall performer, or just for looks?

Glass scales are better for applications needing extreme cleanliness and chemical resistance, like labs. For heavy-duty industrial settings where impacts are likely, stainless steel is superior. "Better" really depends on the job the scale needs to do, as each material has distinct advantages.

As a manufacturer at Weigherps, we help customers make this decision daily. There's no single "best" material, only the best material for your specific needs. To make it clearer, let’s compare glass to the other common high-performance material: stainless steel.

Glass vs. Stainless Steel: A Head-to-Head Comparison

The choice between glass and stainless steel often comes down to the environment where the scale will be used. Both are premium materials, but they shine in different areas.

| Feature | Glass Platform | Stainless Steel Platform |

|---|---|---|

| Hygiene | Excellent. Non-porous and easy to sanitize. | Very Good. Can have microscopic pores. |

| Corrosion Resistance | Superior. Nearly inert to acids and alkalis. | Good. Can be damaged by certain chemicals. |

| Durability | Lower. Brittle and can shatter on impact. | Excellent. Resistant to drops and impacts. |

| Precision Support | Excellent. Very rigid and dimensionally stable. | Very Good. Can slightly warp under extreme loads. |

| Aesthetics | Excellent. Sleek and modern look. | Good. Professional and industrial look. |

| Cost | Generally higher for high-quality tempered glass2. | Varies, but often more cost-effective for durability3. |

For a food processing client, I might recommend a scale with a glass platform for their quality control lab4, where they test small samples and need to prevent cross-contamination5. But for their main factory floor, where 50kg bags are being weighed, a robust stainless steel platform scale is the only sensible choice.

What is a glass scale?

The term "glass scale" sounds simple enough, but it’s not just a slab of window glass. You might wonder what kind of glass it is and how it’s built to actually function as a scale.

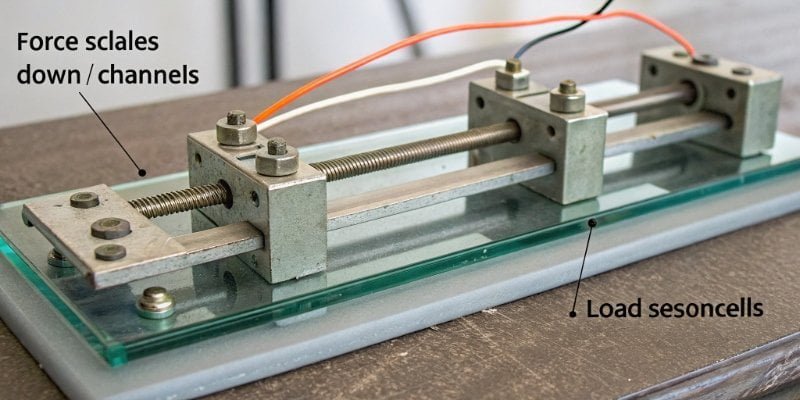

A glass scale is a weighing device that uses a tempered or specialized glass plate as its weighing platform. This platform sits on sensors called load cells. The glass is specifically chosen for its flat, non-porous, and stable properties, which directly help accuracy and hygiene.

A well-made glass scale is a precision instrument where every component is chosen for a reason. Having produced these for years, I can tell you that the magic is in how the parts work together. The glass isn't just a cover; it’s an active and essential part of the weighing mechanism.

The Key Components of a Glass Scale

Let’s break down what makes up a typical glass scale to understand its function better.

- The Glass Platform: This isn't your average glass. For safety and durability, it's almost always tempered glass, which is much stronger and shatters into small, blunt pieces if it breaks. In high-precision analytical balances, the glass is selected for its perfect flatness and uniform density to ensure weight is transferred without any distortion.

- The Load Cells: These are the heart of the scale. Hidden underneath the platform, these sensors are what actually measure the weight. The glass platform’s main job is to perfectly transfer the force of the object onto these load cells6.

- The Frame and Base: The glass platform is mounted on a sturdy frame. This base often includes rubber feet to prevent slipping and, just as importantly, to absorb vibrations7 from the surrounding environment. These vibrations can cause inaccurate readings, so a stable base is critical. This is also how we build in protection for the more brittle glass top.

- The Electronics and Display: This is the brain of the scale. It takes the tiny electrical signal from the load cells, converts it into a weight, and shows it on the screen.

When we produce a glass scale, the most critical step is ensuring the glass is perfectly mounted to the frame. A tiny gap or an uneven surface can lead to inaccurate measurements, defeating the entire purpose of using glass for precision in the first place.

How does a glass scale work?

You place an item on the scale, and a number instantly appears. It feels simple, but how does a solid piece of glass help measure weight so accurately? What’s going on inside?

A glass scale works by channeling the force of an object from the glass platform down to sensors called load cells. These sensors bend microscopically, changing their electrical resistance. This change is measured, converted to a digital signal, and displayed as a precise weight.

The process is a beautiful example of physics and electronics working together. The glass platform plays a role that no other material could play in quite the same way, especially when you get into very precise measurements. It acts as the perfect, unchanging messenger between the object being weighed and the sensors that do the measuring.

The Weighing Process Step-by-Step

Here’s a simple breakdown of what happens in the seconds it takes to get a reading:

- Force Application: You place an item on the scale. The weight of the item creates a downward force.

- Force Transfer: The glass platform is incredibly rigid. It doesn't bend or warp. This rigidity ensures that the full force of the object is transferred perfectly through the support points to the load cells below.

- Sensor Activation: Each load cell contains a delicate component called a strain gauge. As the load cell bends by a microscopic amount under the force, the strain gauge stretches or compresses.

- Electrical Change: This tiny physical change in the strain gauge alters its electrical resistance. The more the force, the bigger the change in resistance.

- Signal Conversion: An internal electronic circuit registers this change in resistance and converts it into a weak electrical voltage signal.

- Digital Display: Finally, an analog-to-digital converter8 (ADC) takes that voltage, translates it into a digital number, and the processor shows it on the screen as your weight.

The glass is the unsung hero here. Its stability ensures that what the load cells feel is the true, direct force of the object, without any loss or distortion.

Why might some doctors prefer mechanical over digital scales?

You go for a check-up and step onto an old-school balance beam scale. With all the modern tech available, why are some medical offices still using this seemingly outdated equipment? Are digital scales untrustworthy?

While many doctors use certified digital scales, some prefer mechanical beam scales for their extreme durability and independence from power. They are also perceived to hold calibration longer and have a simple, trusted mechanism that is less prone to certain types of electronic failure.

This is a great question because it gets to the core of what "reliable" means in a professional setting. It’s not simply about old versus new technology. In our experience supplying scales to various industries, including medical, the choice often comes down to balancing tradition, trust, and workflow needs.

Digital vs. Mechanical in a Medical Context

Many modern clinics have entirely switched to high-end digital scales9, but the balance beam scale holds its ground for a few key reasons.

Reasons for Sticking with Mechanical Beam Scales:

- Built to Last: These scales are tanks. They are made of steel and can function for decades with almost no maintenance.

- No Power, No Problem: They don't need batteries or a power outlet. This eliminates a potential point of failure during a busy day.

- Trusted Calibration: Doctors are trained on them. The physical act of sliding the weights feels direct and less abstract than a digital readout. There’s a belief that they are less likely to drift out of calibration.

The Case for Modern Digital Medical Scales:

- Efficiency: Digital scales provide instant readings, which speeds up patient processing.

- Data Integration: This is a huge advantage. High-end digital scales can connect directly to a patient's Electronic Health Record (EHR). This is in fact a service we help our software vendor clients integrate, eliminating handwriting and manual entry errors.

- Advanced Features: They can automatically calculate Body Mass Index (BMI)10 and other health metrics.

At Weigherps, we produce "medical grade" digital scales. These are held to a much higher standard than a home bathroom scale. They feature superior load cells, robust construction, and official certifications (like OIML or NTEP) that guarantee their accuracy and reliability for medical use. The choice isn't about digital being bad; it's about choosing a professional-grade tool for a professional job.

Conclusion

Glass scales offer unique benefits in hygiene, chemical resistance, and precision. Whether for a lab, kitchen, or industry, understanding the material's strengths ensures you choose the right tool for the job.

-

Understand how chemical resilience affects the choice of materials in scales. ↩

-

Find out why tempered glass is preferred for safety and durability in scales. ↩

-

Understand the key features that enhance the durability of weighing scales. ↩

-

Find out how scales are essential for maintaining quality standards in labs. ↩

-

Learn how the right scale can help prevent cross-contamination in labs. ↩

-

Explore the critical role of load cells in accurate weight measurement. ↩

-

Discover the impact of vibrations on scale performance and measurement accuracy. ↩

-

Learn how ADCs play a crucial role in displaying weight measurements. ↩

-

Explore the benefits of digital scales in improving efficiency in healthcare. ↩

-

Learn how modern scales can provide valuable health metrics like BMI. ↩

Comments (0)