Are you struggling with unstable readings from your analytical balance? This wastes materials and compromises your data. A simple draft shield is the key to achieving consistent, precise results.

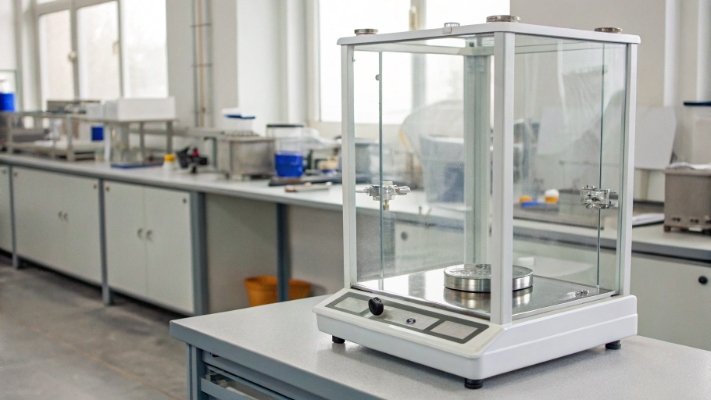

An analytical balance needs a draft shield to protect its highly sensitive weighing sensor. The shield creates a calm environment, blocking disturbances from air currents, dust, and temperature changes. This protection is essential for achieving accurate and repeatable measurements at the milligram level.

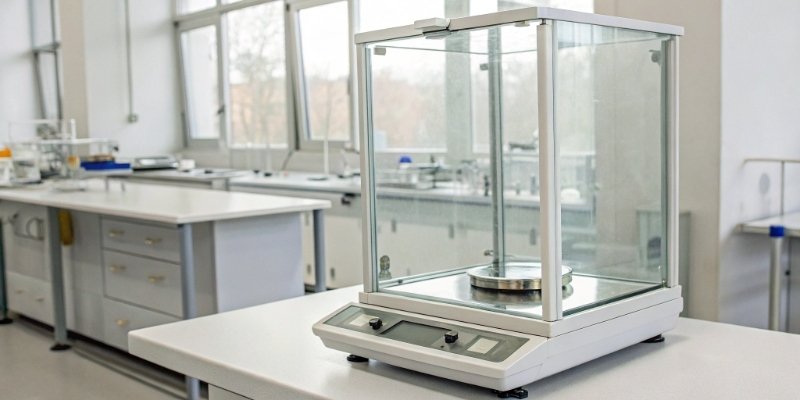

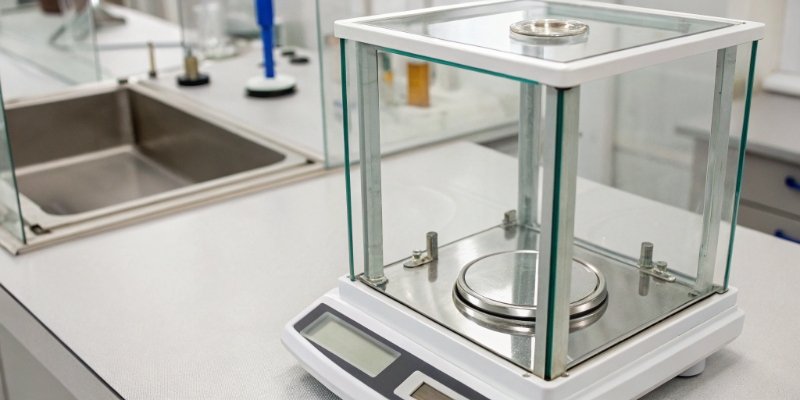

Accuracy is everything when you work with an analytical balance1. We're talking about measurements so fine that even your breath could throw them off. That's why the glass box you see around the weighing pan2 isn't just for show. It plays a critical role in getting the results you need. But how does it really work, and what other factors do you need to consider for perfect measurements? Let's take a closer look together.

What is the function of a draft shield in an analytical balance?

You see that glass box on your balance, but are you sure what it really does? Ignoring its function can lead to flawed data, even if you think you’re being careful.

The main function of a draft shield is to create a stable environment around the weighing pan. It blocks air currents, stops dust from settling, and minimizes temperature changes. This ensures the balance's sensitive mechanism can provide a stable and accurate reading without outside interference.

In my 18 years of experience at Weigherps, I've seen how tiny forces can ruin a precise measurement. An analytical balance is designed to detect changes at a micro-level. The draft shield3 is its first and most important line of defense. It guards against several invisible enemies of accuracy. Based on our extensive testing in the quality control4 department, we know that these small details make a huge difference.

Here are the core functions broken down:

| Function | Why it Matters for an Analytical Balance |

|---|---|

| Blocks Air Currents | Prevents tiny air movements from sources like ventilation or walking by from pushing on the pan, which causes unstable readings. |

| Stabilizes Temperature | Creates a consistent thermal zone inside the shield, stopping small parts in the balance from expanding or contracting due to temperature shifts. |

| Prevents Contamination | Acts as a physical barrier5 against airborne dust and fibers that could land on your sample and add weight, ensuring measurement purity6. |

Each of these functions directly helps the balance do its job correctly. Without the shield, the readings would constantly fluctuate, making it impossible to get a reliable weight.

What is the function of a draft shield?

Draft shields seem like simple boxes, often overlooked on various precision instruments. This oversight means you might not be getting the accuracy you paid for, on more than just balances.

A draft shield’s primary function is to create a still, isolated environment for any sensitive measurement process. It blocks physical disturbances like air currents and dust. It also minimizes thermal interference. This ensures the instrument can perform with maximum accuracy and stability.

At its core, a draft shield is all about isolation. Think of it like an anti-vibration table7, which isolates a device from physical shocks. A draft shield isolates a device from atmospheric disturbances. The principle is the same: remove outside variables to ensure the data you collect is pure.

As a manufacturer, we apply this principle across different product lines. The level of protection depends directly on the level of precision needed.

- Analytical Balances (0.01mg - 0.1mg): A full glass draft shield is non-negotiable. The sensitivity is so high that any air movement will cause problems.

- Precision Balances (1mg and up): A draft shield is highly recommended, especially in environments that are not perfectly still.

- Industrial Scales: These don't typically have a glass shield. However, their robust housing is designed to protect the internal components from larger drafts, dust, and moisture found in industrial settings.

The goal is always to protect the weighing sensor so it can measure only one thing: the mass you place on it.

Why should analytical balances be placed in a draft free environment?

You have a top-of-the-line balance with a draft shield, but your readings are still fluctuating. This can be very frustrating, making you question your equipment. The problem might be its location.

Analytical balances must be in a draft-free environment because their sensors detect the tiny force of air currents. Drafts from ventilation, doors, or people cause unstable readings. This makes it impossible to get an accurate, repeatable weight measurement, even with a draft shield.

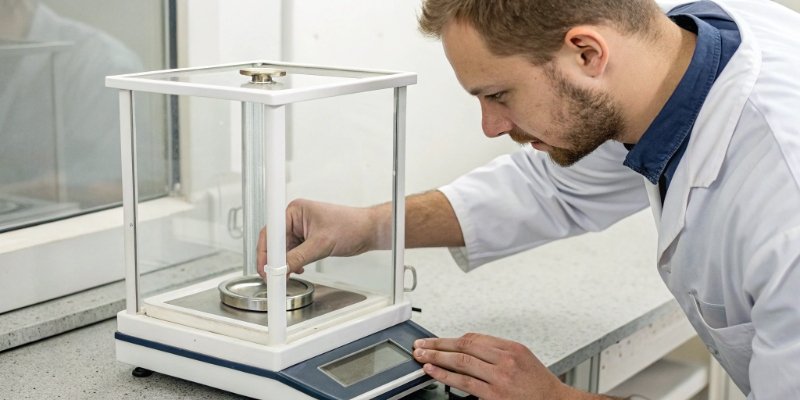

You should think of the draft shield as the last line of defense, not the first. Your primary strategy should be to create a stable environment for the balance. I remember visiting a client's new lab. They were complaining that their brand-new balance was giving unstable readings. When I got there, I immediately saw the problem. They had placed the balance directly underneath a large air conditioning vent. We moved the balance just three meters to a quiet corner of the room, and the issue was solved instantly.

To create the ideal weighing environment, avoid these sources of drafts:

- Air conditioning and heating vents

- Frequently opened doors

- Windows that can be opened

- High-traffic hallways

- Other lab equipment with cooling fans

Placing your balance in a drafty spot is like wearing a raincoat in a hurricane. The coat helps, but it’s much better to not be in the hurricane at all. The calmer the room, the less work the draft shield has to do, and the more stable and accurate your results will be.

What are the requirements for an analytical balance?

Choosing the right analytical balance feels overwhelming with so many technical specs. Making the wrong choice means wasting your budget on equipment that does not meet your needs.

Key requirements for an analytical balance include high precision of 0.1mg or better, repeatability, and linearity. It must also have a draft shield and be placed on a stable surface. Regular calibration is also essential to ensure accuracy over time.

When you select an analytical balance, you're investing in accuracy. As a provider to global brands and wholesalers, we know that reliability is paramount. Our clients, many of whom are software vendors, need hardware that delivers data they can trust. Their own systems often depend on the information our scales provide. That's why we focus on a few core requirements for every analytical balance we produce.

Here are the essential requirements you should look for:

| Requirement | Description | Why It's Crucial |

|---|---|---|

| Environment | A dedicated, draft-free room with a stable temperature and an anti-vibration table. | This is the foundation for all accurate measurements. Without it, even the best balance will fail. |

| Performance Specs | Readability (e.g., 0.1mg), Repeatability (consistency), and Linearity (accuracy across the full range). | These three technical specs define the balance's core ability to weigh accurately and reliably, every time. |

| Physical Features | A draft shield is mandatory. The weighing pan should be correctly sized for your typical samples. | These features physically enable the balance to perform at its specified level of precision. |

| User Functions | An easy calibration process (internal or external), a clear display, and data output options8 for record-keeping. | These make the balance practical, efficient, and useful for daily lab work and data integration. |

At Weigherps, our quality inspection department tests every single one of these aspects before a balance leaves our facility. We ensure it performs perfectly, so you can trust the results it delivers.

Conclusion

A draft shield is not optional for an analytical balance. It is essential for accuracy, working with a stable environment to deliver the precise results you depend on every day.

-

Understanding the workings of an analytical balance can enhance your measurement accuracy and efficiency. ↩

-

Understanding the weighing pan's role can help you optimize your measurement process. ↩

-

Explore how a draft shield can significantly improve the precision of your measurements. ↩

-

Discover how quality control ensures the reliability of your measurement results. ↩

-

Learn how physical barriers can protect your samples and improve accuracy. ↩

-

Explore the concept of measurement purity and its significance in analytical work. ↩

-

Explore how anti-vibration tables can enhance the performance of analytical balances. ↩

-

Explore the various data output options that enhance the usability of analytical balances. ↩

Comments (0)