Ever wonder how humanity measured value before currency? Trading was a guessing game of unfair deals. The simple weighing scale solved this, revolutionizing commerce and society forever.

Weighing scales evolved from simple balance beams in ancient Egypt around 2000 BC to mechanical scales during the Industrial Revolution. The 20th century brought electronic sensors, and today we have smart, IoT-connected scales used in everything from retail to advanced biotechnology.

That is the quick overview. But the journey of the scale is full of fascinating twists and turns. It reflects our own human journey through science and technology. This history shows how each innovation built upon the last. Let's start by looking closer at the very terms we use today.

Is "weighing instrument" the official umbrella term for both scales and balances?

You hear "scale" and "balance" used all the time, but are they the same? This confusion can lead to buying the wrong tool. Knowing the official term helps you specify your needs accurately.

Yes, "weighing instrument" is the official and correct umbrella term. It covers any device used to determine weight or mass. This includes both scales, which measure weight directly, and balances, which compare an unknown mass against a known one.

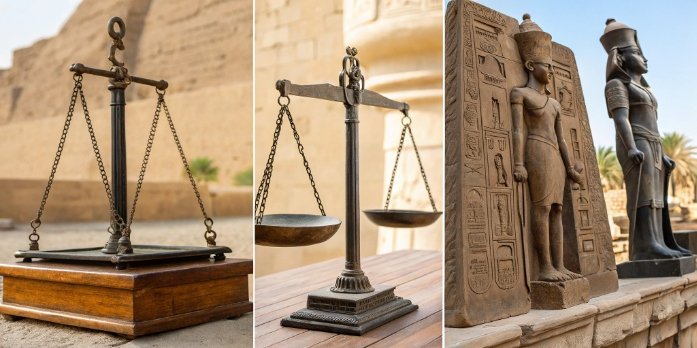

In my 18 years in this industry, I've seen how precise language prevents costly mistakes. The term "weighing instrument1" is what organizations like the International Organization of Legal Metrology (OIML) use. It avoids ambiguity. The very first weighing instruments were balances. Ancient civilizations in Egypt and China, as early as 2000 BC, used a simple beam with two pans. They placed the object in one pan and known weights in the other until the beam was level. This was a direct comparison of masses. Even the more complex Roman steelyard, or gan-cheng in China, used a sliding weight on a lever to find a point of balance. These devices fall under the broad "weighing instrument" category because their purpose is to determine weight.

Here is a simple breakdown:

| Term | Definition | Common Example |

|---|---|---|

| Weighing Instrument | General term for any device that measures weight/mass. | Scales, Balances, Checkweighers |

| Balance | Compares an unknown mass to known masses. | Equal-arm balance, Steelyard |

| Scale | Measures weight (force due to gravity) directly. | Spring scale, Digital scale |

Understanding this helps you communicate your needs perfectly, whether you're buying a simple scale or specifying a complex weighing system.

What is the key functional difference that distinguishes a balance from a scale?

Choosing between a scale and a balance can be confusing. Making the wrong choice means inaccurate measurements and wasted money. Understanding the core functional difference is key to getting the right tool for the job.

The key functional difference is how they measure. A balance compares an unknown mass to a known mass, often using a lever. A scale measures weight, which is the force of gravity on an object, often using springs or electronic sensors.

Let's dive a little deeper into this distinction because it represents a huge leap in technology. For thousands of years, the balance was king. It was an instrument of comparison. Think of the classic image of Lady Justice. She holds a balance, not a scale. It symbolizes comparing two things to find equilibrium. In ancient China, craftsmen developed incredibly precise balances like the dengzi cheng to weigh precious metals and medicines. But balances have limits. They can be slow, and you always need a set of known weights.

The Industrial Revolution2 changed everything. In the 18th century, the spring scale3 was invented. It didn't compare anything. Instead, it used Hooke's Law, which states that the force needed to stretch or compress a spring is proportional to the distance. An object's weight stretches the spring, and a pointer indicates the weight on a dial. This was a true "scale." It measured force directly. Later, large platform scales used systems of levers to weigh huge industrial loads, but they still operated on principles of direct measurement, not just comparison. This shift from comparing to measuring was a fundamental change that paved the way for modern weighing.

Are all modern digital scales technically considered weighing instruments?

Digital technology is everywhere, but does it change the fundamentals of weighing? You might assume "digital" is just a new feature on an old tool. Understanding its technical classification is crucial for integration and compliance.

Yes, absolutely. All modern digital scales are classified as weighing instruments. They use electronic components, like strain gauge load cells, to convert the force of weight into an electrical signal. That signal is then processed and displayed digitally.

This is where my work at Weigherps gets really interesting. The move to electronic scales in the 1950s was the second great revolution in weighing. It wasn't just about replacing a dial with a screen. It was about replacing mechanical parts with solid-state electronics. The heart of nearly every modern industrial scale is the strain gauge load cell. It's a carefully engineered piece of metal that deforms ever so slightly when a load is applied. Glued to this metal is a strain gauge, which is like a tiny, sensitive electronic wire. As the metal deforms, the wire stretches, and its electrical resistance changes.

Our systems measure this tiny change in resistance with incredible precision. This electrical signal is directly proportional to the weight on the scale. A microprocessor then converts this signal into a number you can read on a display. This technology brought about a massive leap in precision, reliability, and speed. It allowed us to build scales that are more rugged and have no moving parts to wear out. It's why all our products can be certified to international standards like CE. They are the pinnacle of weighing instruments.

Besides scales and balances, what other devices are classified as weighing instruments?

You think you know weighing, but the field is broader than just scales. Limiting your knowledge can mean missing out on innovative solutions. Expanding your understanding opens up new possibilities for your business.

The "weighing instruments" category also includes advanced analytical devices. Examples are body composition analyzers, automated checkweighers on production lines, and IoT weighing systems that track data and integrate with enterprise software.

The definition of a weighing instrument has expanded with technology. It's no longer just about finding a number. It's about what you do with that number. Take the medical field, for example. In 2011, companies started making body composition analyzers4. These devices still measure weight, but they also pass a small, safe electrical current through the body. By measuring the impedance, they can estimate metrics like body fat, muscle mass, and water content. It's a weighing instrument combined with another sensor to provide much deeper insight.

In our world of industrial weighing, this trend is even more pronounced. We build IoT electronic scales and custom weighing systems5. These aren't just standalone scales. They are data collection points. A software vendor like yourself would see that our scales can integrate directly into an ERP or a warehouse management system. They can be programmed with AI to automatically identify products or monitor stock levels remotely. We also see "no-contact" weighing technology, spurred on by the pandemic, that allows for measurements without physical touch. This is our vision: to use technology to revolutionize weighing, turning a simple measurement into powerful business intelligence for our customers.

Conclusion

From ancient balances to smart IoT devices, weighing instruments have constantly evolved. This journey reflects our quest for precision, efficiency, and intelligence, shaping modern commerce, science, and industry.

-

Understanding this term is crucial for accurate communication and purchasing decisions in weighing technology. ↩

-

Learning about this impact can highlight the significance of technological advancements. ↩

-

Exploring spring scales can provide insights into their historical significance and practical uses. ↩

-

Understanding these devices can enhance your knowledge of health and fitness measurements. ↩

-

Understanding various weighing systems can help you choose the best solution for your needs. ↩

[…] the factory floor. A precision balance is the perfect device for this. It can be integrated into an IoT system5 to track material usage in a recipe, verify the weight of components before assembly, or perform […]