Are you frustrated by inaccurate measurements from your scale? Bad readings can cause big problems in your business or even at home. I will explain the essentials of weighing scales.

A weighing scale works by converting the force of an object's weight into a digital value. This is done using a sensor, called a load cell, and an electronic processor. The final weight is then shown on a digital display, giving you a precise measurement quickly.

Working in the industrial scale business for over 18 years, I've seen everything from simple kitchen gadgets to massive truck scales. The technology behind them is fascinating, but a lot of people don't understand the basics. This leads to them buying the wrong equipment or not trusting the results they get. Understanding how they work, the different types, and how to maintain them is key to getting reliable results every time. In this post, I’ll walk you through everything you need to know, based on my years of experience building and servicing these machines. Let's get started.

How do modern digital weighing scales work?

Do your scale's readings seem like magic? The process is actually very scientific, but ignoring it can lead to confusion and incorrect use. Let's demystify the technology.

Modern digital scales work through a straightforward process. A sensor, typically a strain gauge load cell, physically bends under weight. This changes its electrical resistance, creating a signal that is amplified, converted into a digital number, and finally displayed as your weight reading.

Let's dive deeper into the core technology. The magic really happens inside the load cell1. At Weigherps, we primarily use strain gauge2 load cells in our industrial scales because they offer a great balance of accuracy and durability3. Here’s the step-by-step flow:

- Force Application: You place an object on the scale platform. Gravity pulls it down.

- Physical Deformation: This force causes a metal structure inside the load cell, called an elastic body, to bend ever so slightly.

- Signal Generation: Tiny electrical conductors called strain gauges are bonded to this structure. As it bends, they stretch or compress, changing their electrical resistance. This creates a tiny analog electrical signal4.

- Signal Processing: This signal is too weak to be useful, so it's sent to an amplifier. After that, an Analog-to-Digital Converter (ADC) transforms the signal into a digital value. A high-resolution 24-bit ADC5, for example, can achieve incredible precision for lab equipment.

- Digital Display: The final digital number is processed by a micro-controller and shown on the screen.

For extremely high-precision tasks, like in a laboratory, an electromagnetic force balance6 (EMFB) sensor is used. It uses an electromagnet to counteract the weight, providing accuracy up to 0.001%. However, for most industrial jobs, a well-made strain gauge scale with an OIML C3 accuracy class7 is the reliable workhorse you need.

What are the different types of weighing scales and their specific uses?

Have you ever used a bathroom scale to weigh a package? Using the wrong scale leads to bad data and frustration. Let me help you match the right tool for the job.

Scales are designed for specific tasks. Kitchen scales handle small weights with 1-gram precision. Industrial platform scales weigh heavy pallets, while high-precision lab balances measure tiny samples. Each type is built with a different capacity, accuracy, and durability to match its intended use.

Choosing the right scale is critical. One of my clients in the food processing industry once tried using a standard warehouse scale in a washdown area. It failed within weeks due to water damage. They needed an IP-rated stainless steel scale8 designed for wet environments. This story highlights why understanding the different categories is so important.

Here’s a breakdown of common types and where they fit best:

| Scale Type | Typical Use Case | Key Features |

|---|---|---|

| Kitchen/Home Scale | Measuring food ingredients, portion control. | Low capacity9 (up to 5kg), 1g readability, compact. |

| Retail Scale | Selling goods by weight in stores. | "Legal for Trade" certified, often has a price calculator. |

| Bench/Platform Scale | Warehousing, shipping, general industrial use. | Medium to high capacity (60kg to 5000kg), very durable. |

| Laboratory Balance | Scientific research, quality control labs. | Extremely high precision (0.1mg or better), enclosed chamber. |

| Specialized Scales | Truck weighing, hazardous environments. | Extra-high capacity, or features like explosion-proof design. |

When you select a scale, think first about your application. What's the heaviest you'll weigh? What's the smallest increment you need to measure? Is the environment wet, dusty, or hazardous? Answering these questions will guide you to the perfect scale, preventing costly mistakes and ensuring you get accurate data for your software systems.

How can I properly calibrate my weighing scale at home or in the workplace?

Do you trust your scale's readings completely? An uncalibrated scale can drift over time, causing errors in recipes, shipping costs, or manufacturing. Let's fix that.

To calibrate a scale, you need a weight of a known, certified mass. First, enter the scale’s calibration mode. Zero it out, then place the calibration weight on the platform. The scale will then adjust itself to match the known weight, ensuring future readings are accurate.

Calibration is a step that many people skip, but it's vital for accuracy. I remember a case where a client was in a dispute over shipping weights. It turned out their 1000kg platform scale was off by 5% because it hadn't been calibrated in over two years. That's a 50kg error on every pallet! We helped them set up a quarterly calibration schedule using certified 20kg weights, which resolved the issue and restored trust with their partners.

For industrial or commercial scales, using certified weights10 is non-negotiable. You should have a set of weights appropriate for your scale's capacity. Here’s a simple guide:

Key Calibration Steps:

- Prepare the Environment: Make sure the scale is on a level, stable surface, away from vibrations or drafts. Let it warm up for about 30 minutes.

- Enter Calibration Mode: This usually involves holding down a button during startup. Always refer to your scale's user manual, as the process varies.

- Establish a Zero Point: With nothing on the platform, confirm the zero point. The scale will record this as its baseline.

- Perform a Span Calibration: The scale will prompt you to place a specific weight on it (e.g., 10kg). Place your certified weight in the center of the platform and confirm. The scale lock in this upper reference point.

For home use, you may not have certified weights. A quick check can be done with an object of a known weight, like a new, unopened 1kg bag of sugar. While not a true calibration, it can tell you if your scale is reasonably accurate. For any business application, however, regular calibration with certified weights is a must. We recommend a full professional calibration at least once a year.

What key features should I consider before buying a weighing scale?

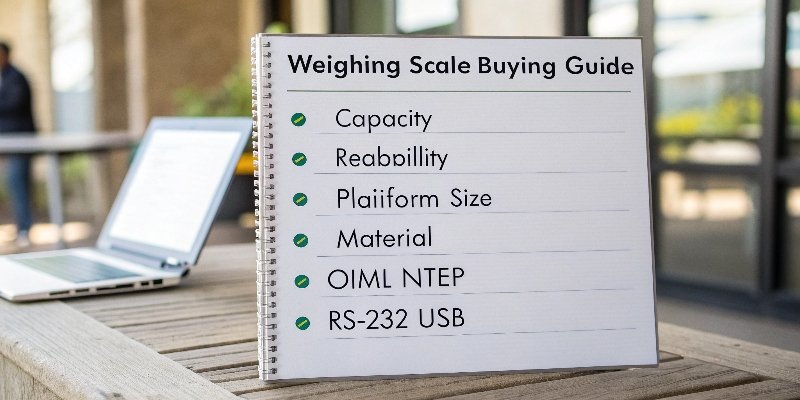

Are you feeling lost in a sea of technical jargon while trying to buy a scale? Choosing the wrong model is a costly mistake. I'll guide you to the features that truly matter.

Before buying a scale, focus on capacity and readability. Also consider the platform size for your items and the scale's material. For business use, check for necessary certifications (like OIML or NTEP) and connectivity options (like RS-232 or USB) for data transfer.

Helping customers choose the right scale is a huge part of my job. As a software vendor, your main concern is reliable data integration. A few years ago, a client developing a warehouse management system bought scales without a data port. Their system was useless until they replaced the hardware. This shows how crucial it is to think about your entire process, not just the scale itself.

Let's break down the essential features to look for, especially from a technical perspective:

| Feature | Why It Matters | What to Look For |

|---|---|---|

| Capacity | The maximum weight the scale can handle. Overloading by just 20-30% can permanently damage the sensor. | Choose a capacity that is slightly higher than the heaviest item you'll weigh. |

| Readability | The smallest increment the scale can display (e.g., 0.1kg). This is not the same as accuracy. | Match the readability to your required precision. A 1000kg scale might have 0.1kg readability. |

| Accuracy Class | Official tolerance for error. Crucial for commercial transactions. | Look for OIML Class III or NTEP certification for most industrial and retail uses. |

| Durability / IP Rating | How well the scale withstands its environment (dust, water). | For wet or dusty areas, look for stainless steel construction and an IP65 rating or higher. |

| Connectivity | The ability to send weight data to a PC, printer, or network. | Essential for software integration. Look for RS-232, USB, or Ethernet ports. |

Finally, consider the manufacturer. A reliable partner like us at Weigherps not only provides a quality product but also offers the technical support needed to integrate it into your systems. Don't just buy a scale; invest in a complete weighing solution.

Conclusion

Understanding your scale's technology, type, calibration, and key features is essential. This knowledge ensures you choose the right tool and trust the results for any application, from home to industry.

-

Learn about load cells, the technology behind accurate measurements in weighing scales. ↩

-

Find out how strain gauges contribute to the precision of modern weighing scales. ↩

-

Learn about the materials and ratings that ensure the longevity of weighing scales. ↩

-

Learn about the conversion process from weight to digital readings in scales. ↩

-

Explore how advanced ADC technology improves measurement precision in scales. ↩

-

Understand the advanced technology of EMFB sensors for high-precision weighing. ↩

-

Learn about the importance of accuracy classes in selecting reliable weighing scales. ↩

-

Learn about the benefits of using IP-rated scales in wet environments. ↩

-

Understand how to choose the right capacity for your weighing needs. ↩

-

Find out why certified weights are essential for accurate scale calibration. ↩

[…] is important to understand the difference between readability and accuracy6. Readability is the smallest increment a scale can display, like 0.1g. Accuracy is how close the […]

[…] price, you are entering a legal agreement with the customer. The National Type Evaluation Program (NTEP2) exists to make sure that agreement is fair. Think of it as a government-backed promise of […]