Struggling to measure tiny weights with your system? Inaccurate small measurements can disrupt your whole process. I'll explain how to find the right load cell for true precision.

The minimum weight a load cell can sense depends entirely on its design and capacity. Specialized, high-resolution load cells can detect changes as small as a few grams, while standard industrial ones might have a minimum detectable weight of 50 or 100 grams. It's all about matching the hardware to the task.

Understanding that minimum value is just the start. If you're developing or implementing a software-driven weighing system, you need to know how this capability is determined and what factors can throw it off. The reliability of your data depends on it. Let's dig deeper into the technical specifics that matter for your projects.

How is the resolution or minimum weight division of a load cell determined?

Feeling confused by terms like resolution and division? Choosing the wrong specs can feed faulty data into your software, creating major downstream problems. Let's clarify how resolution is actually set.

A load cell's resolution is determined by its total capacity and the capability of its analog-to-digital converter (ADC). A higher-bit ADC paired with a lower capacity load cell creates a finer resolution, allowing your system to see and record much smaller weight increments.

To really get this, we have to look at how the components work together. For 18 years, I've seen clients struggle with this, so let me break it down in a way that’s useful for software and systems integration.

The Role of the Analog-to-Digital Converter (ADC)

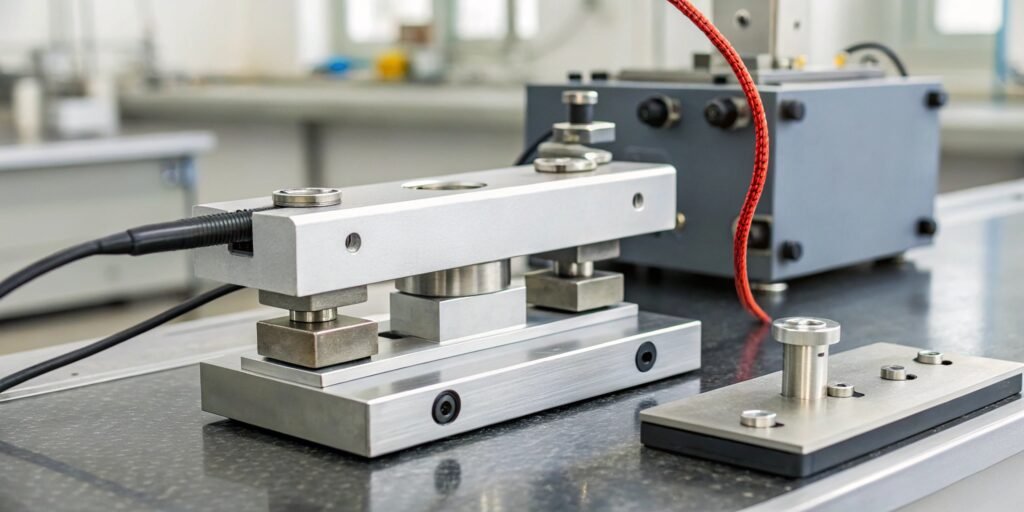

A load cell1 itself is an analog device. It converts force into a tiny electrical signal, usually measured in millivolts. Your software can't read that directly. That signal must be converted into a digital value by an ADC, which is located in the weighing indicator or transmitter. The quality of this ADC is measured in "bits," which determines how many individual "steps" or "counts" it can divide the load cell's full signal into. A 16-bit ADC has 65,536 counts, while a 24-bit ADC has over 16 million. More counts mean a finer measurement.

Calculation and Practical Example

The relationship is simple: the minimum division is the load cell's total capacity divided by the number of usable ADC counts. Let's see how this affects the data your system gets.

| Total Capacity | ADC Counts | Minimum Division (Resolution) |

|---|---|---|

| 100 kg | 10,000 | 10 g |

| 100 kg | 50,000 | 2 g |

| 10 kg | 50,000 | 0.2 g |

As you can see, simply changing the load cell's capacity or using a better indicator dramatically changes the data granularity. For your software, this is the difference between tracking grams and being blind to anything less than 10 grams.

What factors limit the sensitivity of a load cell for small measurements?

Are environmental factors causing your weight readings to drift? This "noise" can ruin the precision of your small measurements, making your data unreliable. Let's look at what limits a load cell's sensitivity.

A load cell's sensitivity is limited by electrical noise, temperature fluctuations, physical vibration, and its own internal imperfections like creep and hysteresis. These factors create a "signal floor," making it hard to distinguish a tiny weight change from background interference.

When you are trying to capture milligram-level changes, the real world often gets in the way. Your software needs clean, stable data, but the hardware is constantly fighting against interference. Understanding these limits is key to designing a robust system.

Environmental and Mechanical Interruptions

The signal coming from a load cell is very low voltage. This makes it highly susceptible to outside interference.

- Electrical Noise: Nearby equipment like motors, variable frequency drives (VFDs), or even fluorescent lights can introduce electrical noise that corrupts the signal. Proper shielding and grounding are essential.

- Vibration: A nearby conveyor belt or stamping press can cause vibrations that make the weight reading jump around. Your system needs physical dampening or software filtering to handle this.

- Temperature: Metal expands and contracts with temperature. Although load cells have built-in temperature compensation, rapid or extreme temperature swings can still cause the reading to drift.

Inherent Material Properties

Even in a perfect environment, the load cell itself has physical limitations.

- Creep: If you place a weight on a scale and leave it, the reading might slowly change over time. This is called creep2—the material of the load cell deforming slightly.

- Hysteresis: The reading for a 10 kg weight might be slightly different if you placed it on an empty scale versus if you arrived at it by removing weight from a 20 kg load. This difference is hysteresis3.

For a technical director, accounting for these physical limitations in your software logic or system setup is non-negotiable for achieving reliable results.

How does a load cell's total capacity affect its ability to detect small weight changes?

Do you think a high-capacity load cell is a good one-size-fits-all solution? Using an oversized cell is a common mistake that will make your system completely blind to the small weight changes you need to measure.

A load cell's total capacity is inversely related to its ability to detect small changes. A lower-capacity cell is physically more responsive to small forces, producing a larger relative signal. This stronger signal makes it much easier to accurately measure tiny increments.

I once had a client trying to measure 50-gram ingredient additions in a 1,000 kg mixing tank. Their data was all over the place. The problem wasn't the software; it was the hardware. They were using a load cell designed to weigh tons to measure something that weighs less than a tennis ball.

The Signal-to-Noise Ratio

Think about it this way. A 50-gram weight on a 5 kg load cell creates a significant change in the electrical signal—it's a loud, clear voice. That same 50-gram weight on a 1,000 kg load cell produces a signal change so small it's barely a whisper. This whisper can easily get lost in the background electrical noise we talked about earlier. To get good data, you need a strong signal, which means you must match the load cell's capacity4 closely to the weight you're actually measuring.

Best Practices for Selection

A good rule of thumb is to choose a load cell where your typical target weight falls somewhere between 25% and 75% of its total capacity. This gives you a strong signal without risking overload. Here’s a simple comparison:

| Feature | Low-Capacity Load Cell (e.g., 5 kg) | High-Capacity Load Cell (e.g., 1000 kg) |

|---|---|---|

| Sensitivity | High (detects small changes easily) | Low (small changes create a tiny, noisy signal) |

| Ideal Use Case | Laboratory weighing, small batching, quality control | Tank weighing, vehicle scales, heavy industrial use |

| Vulnerability | Susceptible to damage from overload | Robust, but lacks precision for small weights |

Choosing the right capacity is the single most important hardware decision for ensuring your software gets the accurate, high-resolution data it needs.

What is the difference between a load cell's resolution and its accuracy at low weights?

Are you confusing resolution with accuracy? It's a very common mistake, but it can lead you to build a system that is precisely and consistently wrong. I'll explain the critical difference.

Resolution is the smallest weight increment a scale can show you, like 0.1 gram steps. Accuracy is how close that displayed reading is to the true, physical weight. You can easily have a high-resolution scale that is inaccurate.

This distinction is absolutely vital for anyone responsible for data integrity5. Just because a number on a screen has three decimal places doesn't mean it's correct. As a weighing expert, I stress this point with every systems integrator I work with.

Understanding Resolution

Resolution is a digital specification. It is a function of the hardware's capabilities—specifically, the ADC and the indicator’s programming. A scale with a resolution of 1 gram will display weights in 1-gram steps: 10g, 11g, 12g. It physically cannot show you a value of 10.5g. It will round it to either 10g or 11g. High resolution is great, as it gives you a very granular picture, but it's only half the story.

Understanding Accuracy

Accuracy is a measure of correctness against a known standard. It’s an analog-world problem. Accuracy is affected by all the real-world factors we discussed: temperature, linearity (how consistent the error is across the full range), hysteresis, and most importantly, calibration. You can have a scale that resolves to 0.01g, but if it's not calibrated correctly, it might read 10.52g for a certified 10.00g weight. The reading is high-resolution6, but it's inaccurate. For your software, this means you'd be processing a stream of precisely wrong data, which can be even more dangerous than noisy data.

Conclusion

Selecting a load cell requires balancing capacity against your required resolution and accuracy. Understanding these core factors ensures you get reliable, meaningful data for your specific application, especially when measuring small weights.

-

Explore this resource to understand the fundamentals of load cells and their applications in precision measurement. ↩

-

Learn about creep and its implications for accurate weight readings in load cell applications. ↩

-

Discover how hysteresis can impact the accuracy of load cell measurements and how to mitigate it. ↩

-

Learn about the relationship between load cell capacity and its ability to detect small weight changes. ↩

-

Explore the importance of maintaining data integrity for reliable weight measurement systems. ↩

-

Understand the significance of resolution in load cells and how it affects measurement accuracy. ↩

[…] small ones, will give you wrong readings. The environment also matters a great deal. We look for a stable temperature2, ideally around 20°C (68°F), and make sure there are no vibrations from nearby machinery. We […]

[…] After that, an Analog-to-Digital Converter (ADC) transforms the signal into a digital value. A high-resolution 24-bit ADC5, for example, can achieve incredible precision for lab […]

[…] inherit all the same limitations we’ve already discussed: temperature sensitivity, creep, and hysteresis6. So, when you’re troubleshooting a pressure system, you might actually be dealing with a […]