Choosing the right scale can be confusing. The wrong one can hurt your accuracy and budget. Let's find the best fit for you.

Digital scales are best for accuracy, smart features, and use in harsh environments. Analog scales are cheaper and simpler, making them suitable for basic weighing where high precision isn't needed.

The choice between digital and analog isn't just about old versus new technology. It’s about getting the right tool for your specific job. I've spent years helping clients make this decision, and it always comes down to what you need the scale to do. Let's dig into the details to see which one makes sense for your business.

Which is better, an analog or digital weighing machine?

Confused by technical specs? Worried you'll overspend on features you don't need? I'll explain the real-world differences between digital and analog scales for you.

Digital scales are better for precision, data integration, and overall reliability. Analog scales are better for simple, low-budget tasks, especially where there's no power. The "better" choice depends on your needs.

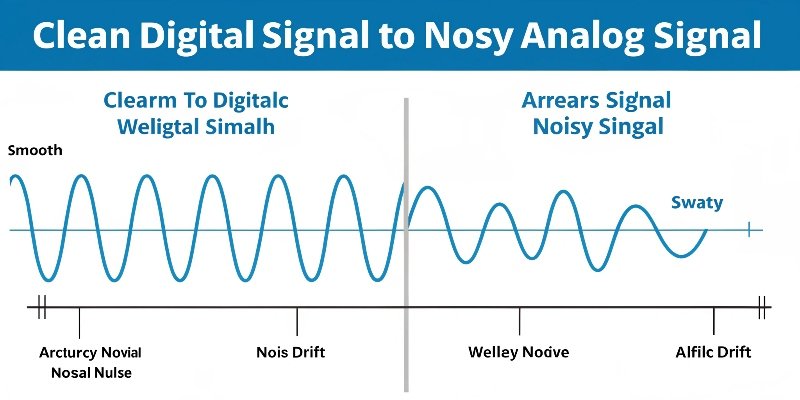

When our clients ask which is "better," I always ask them about their operation. The answer lies in how these two types of machines work. A digital scale measures weight and converts it into a clean, digital signal right at the source. An analog scale sends a weak electrical signal that can be affected by many things. This core difference impacts everything from accuracy to maintenance. For a business that relies on data, like a software provider, the ability of a digital scale to communicate clearly with other systems is a huge advantage. They are not just weighing tools; they are data points in your production line.

Let's compare their core performance head-to-head.

Core Performance Breakdown

| Feature | Digital Weighing Machine | Analog Weighing Machine |

|---|---|---|

| Signal Processing | Strong digital signal, high anti-interference. Can travel up to 1200 meters. | Weak analog signal, easily affected by noise. Requires shielded cables. |

| Accuracy | Very high, can reach 0.01% FS. | Lower, around 0.1% FS. Affected by temperature changes. |

| Stability | Excellent. Built-in temperature compensation1 for stable, long-term accuracy. | Fair. Needs regular calibration to correct for drift. |

| Features | Smart functions like auto-zero tracking and self-diagnostics2. | Basic weighing function only. No smart features3. |

| Maintenance | Low. Modules can be swapped without needing a full recalibration. | High. Requires regular calibration, which means downtime and labor costs. |

What kind of weight scale is most accurate?

Do small measurement errors cause big problems in your work? If you need the highest precision, let’s pinpoint the most accurate option available on the market today.

Digital weighing machines are, by far, the most accurate. Their design minimizes electrical noise and temperature effects, allowing them to deliver consistently precise readings, often with an accuracy of 0.01% of full scale.

Accuracy is the number one reason our clients in the pharmaceutical, chemical, and laboratory sectors choose digital. The secret is in the load cell4. In a digital scale, the load cell immediately converts the physical weight into a digital signal. This digital information is a clean series of ones and zeros that isn't easily disturbed. An analog signal, on the other hand, is a continuous electrical wave that can be distorted by everything from nearby power lines to temperature shifts in your facility. This distortion leads to inaccurate readings.

Why Digital Signals Win

I like to think of it like this: an analog signal is like trying to have a conversation in a crowded, noisy room. The message can get lost or misunderstood. A digital signal is like sending a clear text message. The information arrives exactly as it was sent. This reliability is crucial when your product quality or formula depends on exact measurements. In our experience, clients who switch from analog to digital see an immediate drop in batch inconsistencies and material waste.

Real-World Accuracy Examples

In a lab, a scientist needs to measure 0.1mg. A digital balance can do that. On a construction site, weighing gravel, being off by a few pounds doesn't matter. An analog scale is fine there. For any process where precision is tied to profit, digital is the only way to go.

Do analog scales work better?

Are you thinking that older technology might be simpler and more reliable? Wondering if a basic analog scale is all you really need? Let's look at the few cases where "simpler" is truly better.

Analog scales work better only in very specific situations. Think of remote farms without electricity or scrapyards where rugged simplicity and low cost are more important than perfect accuracy.

I'll be honest, we don't sell many analog industrial scales5 anymore. However, they still have a place. Their main advantage is their simplicity. They are purely mechanical devices, so they don't need a power source. This makes them useful for basic weighing in off-grid locations. They are also very cheap to buy upfront. If your budget is extremely tight and you just need a rough estimate of weight, an analog scale can seem like a good choice. It’s a tool that works on a basic level.

The Case for Simplicity

In some very rough environments, like a mine or a rural market, a durable mechanical scale can take a lot of abuse. There are no electronics to fail from moisture or impact. The user can see the needle move and get an immediate, though not perfectly accurate, reading.

The Hidden Costs of Analog

But for most businesses, the initial savings are quickly lost. Analog scales6 require constant calibration. That means paying a technician to come out and adjust it, and production stops while it's being serviced. They are also very sensitive to temperature changes, which can lead to costly errors in your product batches. Over time, we've seen their measurements drift by as much as 0.5%. And most importantly for a tech-focused client, they can't communicate. You can't connect an analog scale to your software or factory management system. It's a data dead end.

Is digital weight more accurate?

Do you still have doubts about digital accuracy? Are you unsure if the extra cost provides real performance benefits? I will show you exactly why digital measurement is superior for business.

Yes, digital weight measurement is fundamentally more accurate. It captures weight and converts it to a clean digital signal inside the load cell, eliminating the signal noise and drift that plague analog systems.

The difference in accuracy comes from the technology inside the scale. When you place an item on a digital scale, a tiny, smart processor inside the load cell goes to work. It doesn't just measure the weight; it also measures the current temperature and automatically adjusts the reading to compensate. This ensures the weight it reports is true, whether your factory is hot in the summer or cold in the winter. Analog scales can't do this. Their simple electrical signal will change with the temperature, giving you different readings for the same item at different times of the day.

Inside the Digital Load Cell

This built-in intelligence is a game-changer. Our digital load cells also have self-diagnostic capabilities. They can actually tell you if there’s a problem before it leads to a major failure. For our clients, this means less unexpected downtime and more control over their production lines. This is a level of reliability that analog systems simply cannot offer.

Practical Advantages of Digital Accuracy

This improved accuracy has huge practical benefits. It ensures consistency from one batch to the next. It allows you to connect multiple scales into a single system and trust that they all read the same. For companies working in tough conditions, many of our digital systems, like those with an IP68 rating7, are completely sealed against dust and water. They are built for the reality of the industrial world.

Conclusion

For precision, data, and reliability, choose a digital scale. For simple, low-cost tasks where accuracy is not critical, an analog scale may be enough. Always match the technology to your needs.

-

Explore how temperature compensation improves the accuracy of digital scales in varying conditions. ↩

-

Understand how self-diagnostic features can prevent failures and reduce downtime in operations. ↩

-

Discover the advanced functionalities of digital scales that enhance usability and efficiency. ↩

-

Learn about the critical role of load cells in ensuring accurate weight measurements. ↩

-

Find out which industrial scales provide the best accuracy for demanding environments. ↩

-

Learn about the specific scenarios where analog scales excel, especially in low-budget or off-grid situations. ↩

-

Discover how an IP68 rating ensures durability and reliability in harsh conditions. ↩

[…] industrial weighing, this trend is even more pronounced. We build IoT electronic scales and custom weighing systems5. These aren't just standalone scales. They are data collection points. A software vendor like […]